Ammonium Paratungstate (APT) to Synthesis W-A12O3 Nanoscale Composite

- Details

- Category: Tungsten Information

- Published on Friday, 12 June 2020 05:45

Ammonium paratungstate (APT), as a significant starting material for tungsten, which can be derived into the majority of tungsten products. Wolframite or scheelite (CaWO4) concentrates are the two common materials are APT. There are two important steps in production of metallic tungsten from APT. The first step is thermal reduction of APT powder by heating at 400–900 °C, which leads to ammonia and water elimination as well as the crystallization of tungsten trioxide (W03). In the second step, an even higher temperature is required. WO3 powder was heated under H2 at 600–1100 °C, and metallic tungsten is then prepared.

The high energy consumption from the above procedures brings a high expenditure, which makes the production of nanoscale tungsten particles unachievable. Many new producton methods of nanostructured tungsten has been introduced these days. Mechanical alloying and mechanochemical synthesis (MCS) have been considered as methods with commercial applications. They need simple and inexpensive equipments, and has lower requirement on temperature. MCS applies mechanical energy to enhance chemical reactions. Kinetics of these reactions depends on both heating and milling and takes place in gradual or MSR (mechanically induced self-propagation reaction) modes.

W-A12O3 nanoscale composite has been produced by mechanical milling of ammonium paratungstate (APT) and aluminum (Al) powder mixture at room temperature. The preparation procedures are as follows:

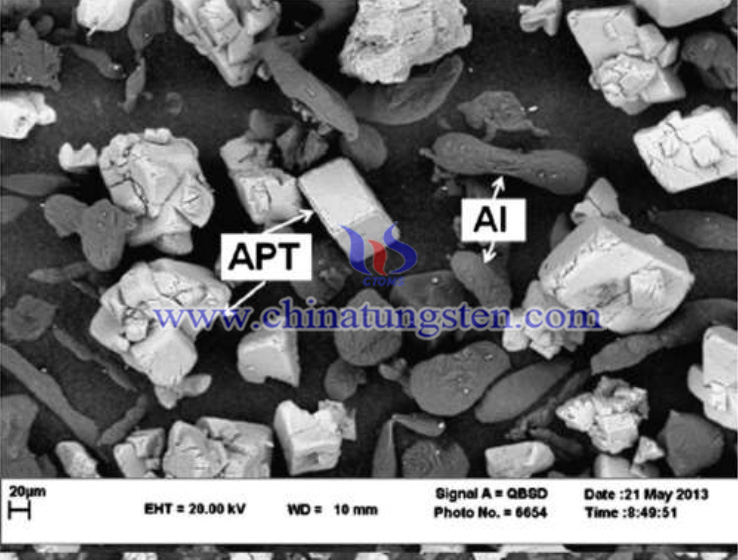

A mixture of APT (99%) and Al powder (99.5%) was prepared. To reduce the effect of surface oxidation, Al was used 10 wt.% over stoichiometric. 5 g of mixture was milled in high energy planetary ball-mill for different milling times more than 24 h at room temperature. The rotation speed of mill was 300 rpm, and the weight ratio of the balls to the powder (BPR) was 40:1. The milling media was bearing steel balls with diameters of 10 and 12 mm.

The Clystal structures of the ball-milled powders were characterized by X-ray diffraction (XRD).The XRD patterns were recorded. The mean grain size of obtained powder was calculated. Morphology of the produced powders was studied by SEM.

In short, W-A12O3 nanostructured composite has been successfully prepared via mechanical reduction of APT. The obtained composite was nanostructured and agglomerated with regular rounded shape. The procedures are simple and has lower energy consumption and takes place in lower temperature.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com