Production Process of Tungsten Carbide Blade

- Details

- Category: Tungsten Information

- Published on Wednesday, 03 June 2020 17:45

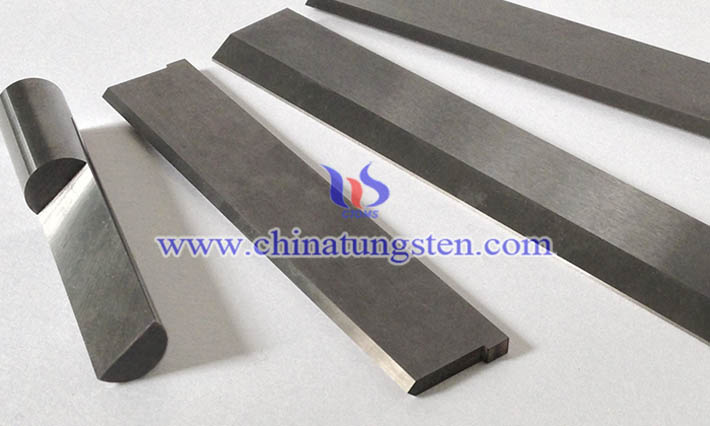

Production process of tungsten carbide blade is the focus of researchers as it greatly affects the quality of blades. Production processes of tungsten carbide blades include powder production, powder compacting, high temperature sintering, blade grinding and other processes.

More details, please visit:

http://www.tungsten-carbide.com.cn/tungsten-carbide-blade-bar.html

Production Processes of Tungsten Carbide Blade

Step One: Powder production. The ore raw materials are sintered in a vacuum furnace or a hydrogen reduction furnace to extract high-temperature carbides WC, TiC, TaC, NbC and metal binders Co, Mo, Ni, etc., to form powder metallurgy products, sieved and ground to make the powder size between 1 and 2 μm of high purity, add other formula materials, raw materials are proportioned according to the specified composition ratio, add alcohol or other media and wet grind in wet ball mill to make them fully mixed and crushed, after drying and sieving, a pressing agent such as wax or glue is added, and then dried and sieved to obtain a mixture. Put the mixture to a container and spray dried, then put it in a container and stored compactly.

Step Two: Powder compacting. Put the mixed powder in the container into the mold and center pin corresponding to the product model, press, demold to remove the bottom and top punches, and take out the matrix of the compressed blade model.

Step Three: High temperature sintering. Put the blade substrate into the tray, and then put the tray into the sintering furnace for high-temperature sintering at 1300-1500 °C. Take it out for cooling and put it in the grid for shrinkage.

Step Four: Blade grinding. Formed blade base is made into a blade through top and bottom surface grinding, free profiling grinding, profiling cutting, chamfering, negative chamfering, peripheral treatment, cutting edge cutting, chip flute grinding, blade tip passivating, microscope enlarged inspecting, cutting edge passivating, and checking whether there is defect.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com