How to Improve Tungsten Carbide Shield Cutter Properties?

- Details

- Category: Tungsten Information

- Published on Thursday, 07 May 2020 08:57

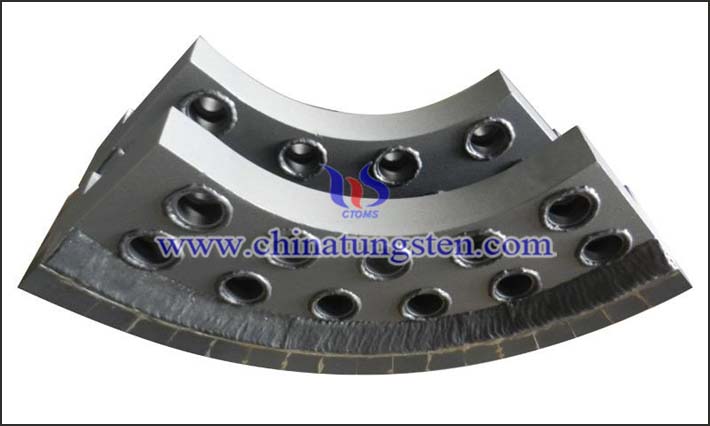

How to improve tungsten carbide shield cutter properties? Tungsten carbide has unique properties such as wear resistance, corrosion resistance, high hardness, and impact resistance, so it is often used to manufacture heads of cutters such as disc cutter, serrated knife or scraper for applying to a tunnel boring machine. While these cutters will inevitably break and wear. To improve service life of tungsten carbide cutters, some researchers have proposed a method to improve performance of tungsten carbide shield cutter.

More details, please visit:

http://www.tungsten-carbide.com.cn/tungsten-carbide-blade-bar.html

A Method for Improvement of Tungsten Carbide Shield Cutter Properties

Graphene is uniformly dispersed in an organic solvent in advance to form a dispersion liquid, and then mixed with coarse-grained WC powder and Co powder, and then successively subjected to ball milling, drying, and sintering processes to obtain tungsten carbide.

In this method, graphene is ultrasonically dispersed in an organic solvent and ball milled with WC powder for a long time to achieve a good mixing effect, thereby achieving uniform structure in the subsequent sintering process and reduce sintering defects; and the excellent thermal conductivity and comprehensive mechanical properties of graphene are used to improve the thermal conductivity and mechanical property of tungsten carbide.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com