Working Principle of Tungsten Carbide Flowdrill

- Details

- Category: Tungsten Information

- Published on Tuesday, 05 May 2020 09:28

What is working principle of tungsten carbide flowdrill? You know, tungsten carbide flowdrill is a wear-resistant and high-temperature resistant drill bit for flowdrilling processes. The flowdrilling process is a chipless machining technology that processes holes and bushes on a metal sheet or tube at one time. Such a process has completely replaced the process of welding and riveting a nut on a thin-walled workpiece. Therefore, it is necessary for us to understand the working principle of flowdrill.

More details, please visit:

http://www.tungsten-carbide.com.cn/tungsten-carbide-drill.html

Working Principle of Tungsten Carbide Flowdrill

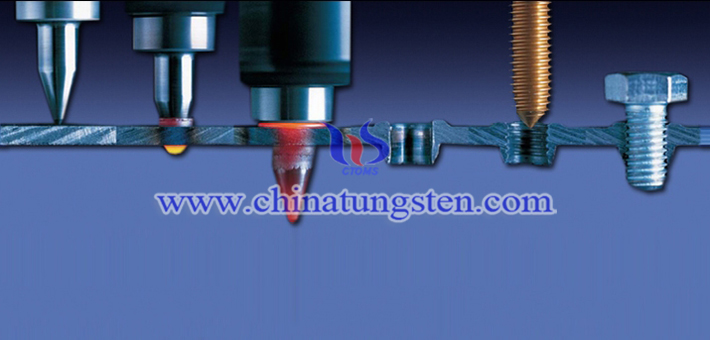

The high-speed rotating tungsten carbide flowdrill contacts the surface of the workpiece, and generates intense heat of more than 600 degrees due to friction with the metal surface. Rapid feed of the drill bit generates pressure, and the high temperature generated can quickly soften the surface of the workpiece locally. While drill is squeezed through, the softened metal part is stretched into a metal bushing with three times the original thickness. The entire process only takes 2-6 seconds without changing structural performance of metal workpiece. And the metal bushing is formed into to screw thread to withstand high-strength tensile and torsional forces.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com