A Simple Hydrothermal Tungsten Oxide Nanowire Gas Sensitive Material

- Details

- Category: Tungsten Information

- Published on Wednesday, 09 October 2019 23:53

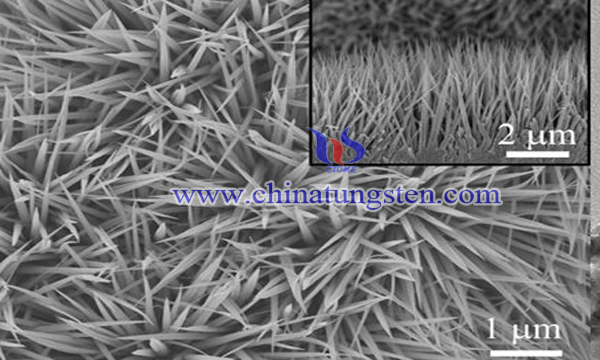

In view of the problems existing in the preparation of tungsten oxide nanowires and their gas sensing applications, researchers have prepared tungsten oxide nanowires gas sensing materials in a wide range by simple hydrothermal method, and then provided a tungsten oxide nanowire sensor with high sensitivity, good repeatability and high stability for H2, CO and NH3. The operation process is as follows:

1.Preparation of tungsten oxide nanowires:

(1) Sodium tungstate solution with weight ratio of 1.5% to 8.0% was prepared by dissolving appropriate amount of sodium tungstate in a certain amount of deionized water. After magnetic stirring in ice-water bath for 1 hour, a colorless and transparent sodium tungstate solution was formed.

(2)Slowly drop appropriate amount of 3M/L hydrochloric acid into (1) solution and stir continuously for 1.5 hours to form pale yellow micelle solution. The micelle solution is centrifuged at 4000 rpm for 20 minutes.

(3)The product of centrifugal separation was evenly dispersed in 11.5M/L potassium sulfate solution to form a mixed solution. 80 ml of the mixed solution was transferred to 100 ml reactor for hydrothermal reaction. The reaction temperature was 180-270 C and the reaction time was 12-120 hours.

(4)After washing the hydrothermal products in (3) repeatedly with deionized water and anhydrous alcohol and drying for 12 hours at 70 ℃, the hexagonal tungsten oxide nanowires with high specific surface area can be obtained, and the nanowires can maintain stable hexagonal phase structure below 450 ℃.

2.Gas sensing applications of tungsten oxide nanowires:

(1) Preparation of Gas Sensitive Material Slurry

The tungsten oxide nanowires prepared above are used as main materials, ethyl cellulose and terpineol as binders, and glass materials are added to enhance the adhesion between sensitive materials and alumina substrates. The slurry of sensitive materials is prepared by mixing the above materials proportionally and stirring evenly.

(2) Component sintering

The slurry screen was printed on the alumina substrate with silver electrodes and lead wires, fully dried in air at 80 ℃, and sintered in a box furnace at 300 - 450 ℃ for 1 - 2 hours to prepare the tungsten oxide nanowire gas sensor module.

(3) Component aging

A tungsten oxide nanowire gas sensor was fabricated by aging the sintered gas sensor at 300 ℃ for 120 hours.

The prepared tungsten oxide nanowires have large specific surface area and high thermal stability. Moreover, the nanowires have high sensitivity, good repeatability and high stability for low concentration (1-100 ppm) H2, CO and NH3 in gas sensing applications.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com