Modified Tungsten Trioxide Nanofilm Gas Sensitive Material

- Details

- Category: Tungsten Information

- Published on Sunday, 06 October 2019 11:08

The increasing development of modern industry not only improves people's living standards, but also brings unavoidable damage to the ecological environment. Nitric oxide (NO) emitted from organic matter decomposition, fossil fuel combustion and chemical industry is a common atmospheric pollutant, which is one of the main substances to form acid rain and photochemical smog, and has great damage to the environment. Therefore, the research of nitrogen dioxide gas sensor components has important significance and development prospects.

Based on p-type single crystal germanium, the preparation of tungsten trioxide nano-film on the substrate by sol-gel method can realize the new room temperature gas sensing with high sensitivity and easy compatibility with microelectronic process technology. Component. The manufacturing steps are:

(1) Cymbal cleaning

A p-type single-sided polished single crystal piece having a resistivity of 10 to 15 n·cm and a thickness of 400 um and a <100> crystal orientation was cut into a rectangular crucible base having a size of 2.5 cm x 1 cm, and placed in a hydrogen peroxide solution. : Soaked in concentrated sulfuric acid=1:3 cleaning solution for 40 minutes to remove surface organic pollutants; rinse with deionized water and soak in hydrofluoric acid aqueous solution with 5% mass fraction for 30 minutes to remove surface oxide layer; rinse with deionized water. Then, it is ultrasonically cleaned in acetone solvent, absolute ethanol and deionized water for 15 minutes, and the surface ions and organic impurities are washed away and dried for use.

(2) Sputtered platinum fork electrode

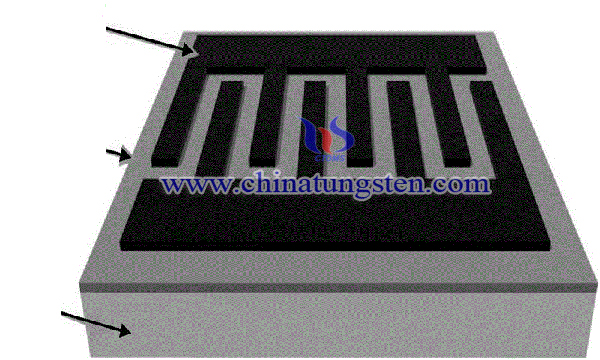

The sample of the p-type single crystal ruthenium substrate after washing and drying is placed in a vacuum chamber of a DPS-III ultra-high vacuum target magnetron sputtering apparatus, and the target material is metal platinum having a quality purity of 99.95%, and the working gas is Argon gas with a purity of 99.999%, a bulk vacuum of 4x10-4Pa, a substrate temperature of room temperature, an argon gas flow rate of 23 mL/min, a working pressure of 2 Pa during sputtering, a sputtering power of 90 W, and sputtering At a time of 10 min, a platinum interdigitated electrode was formed by sputtering on a single polished surface of the ruthenium substrate.

(3) Preparation of gas sensor element based on tungsten trioxide film

A tungsten trioxide film was grown on the polished surface of a single crystal germanium substrate sputtered with a platinum interdigital electrode by a sol-gel spin coating method. The precursor hexachlorochloride and absolute ethanol are used to prepare a sol according to a quality ratio of 1:10, and the prepared sol is uniformly applied to a polished surface of a ruthenium plate sputtered with a platinum interdigitated electrode by a spin coating method. The number of glues was 3 times, the amount of glue used was 8 drops each time, the spin coating speed was 2500r/min, and the spin coating time was 60s. Then, the spin-coated sample substrate was placed in a muffle furnace for heat treatment at a heat treatment temperature of 400 ℃ and a heat treatment time of 2 h to prepare a gas sensor element based on a tungsten trioxide film.

The ruthenium-based material is used as the substrate to realize the transformation of the tungsten trioxide pn-type structure, further improve the sensitivity of the tungsten trioxide nanofilm gas sensitive material to nitrogen oxide gas, and overcome the disadvantages of the traditional working temperature of the tungsten trioxide gas sensitive material. The tungsten trioxide gas sensitive detector can detect the extremely low concentration of nitrogen oxide gas at room temperature, and has excellent gas sensitivity characteristics such as rapid response, high selectivity and good recovery.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com