Tungsten Carbide Composites Containing Alumina Particles and Silicon Nitride

- Details

- Category: Tungsten Information

- Published on Sunday, 08 September 2019 22:30

Traditional cemented carbide is composed of hard WC phase and low melting point metal bonding phase. WC has high hardness, excellent oxidation resistance and corrosion resistance. The addition of metal bonding agent will inevitably weaken the hardness, wear resistance, oxidation resistance and corrosion resistance of the alloy. In addition, it is likely to make the alloy more stable. The decrease of wear resistance, especially the softening and oxidation of metal bond at high temperature, will make WC cemented carbide prone to over-rapid failure, which limits the application scope of WC cemented carbide.

A tungsten carbide composite containing alumina particles and silicon nitride whiskers has been proposed. Its properties are similar to those of tungsten-cobalt alloys. The manufacturing steps are as follows:

Step 1: Preparing materials

WC, Al2O3 and a Si3N4 powders were proportioned into raw materials according to the following quality percentages: WC 87-99%, Al2O3 0.5-3%, a Si3N4 0.5-10% of particles 0.5-10 um, and the rest were unavoidable trace impurities.

Step 2: Powder dispersion and mixing

The raw material powders are placed in organic or inorganic solvents, the agglomerated powders are dispersed by compulsory means, and then the slurries are wet low energy ball milled to produce mixed slurries.

Step 3: Powder drying and sieving

The mixture slurry is dried in a drying furnace until the residual solvent is less than 1%. Then it is crushed and sifted to obtain a mixed powder with particle size less than 250 um.

Step 4: Sintered powder

Spark plasma sintering (SPS) or hot pressing sintering (HPS) were used to form and sinter the above mixed powders.

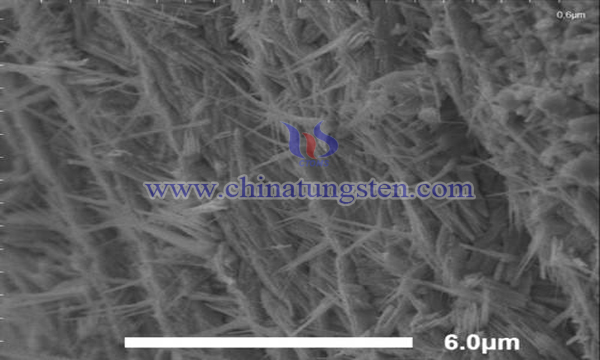

Although relatively inexpensive Al2O3 and a Si3N4 powders are used as raw materials, the prepared WC composite is a kind of WC composite without any metal bonding phase, which is toughened by Al2O3 particles and in situ in situ beta Si3N4 whiskers. It has excellent hardness, wear resistance, high temperature mechanical properties and medium toughness. It is suitable for cutting tools such as indexable blades, plastic processing tools such as drawing dies, and cutting tools such as punching and shearing dies. It is an unbonded phase WC material with higher toughness than pure WC or WC material toughened by a single ceramic component.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com