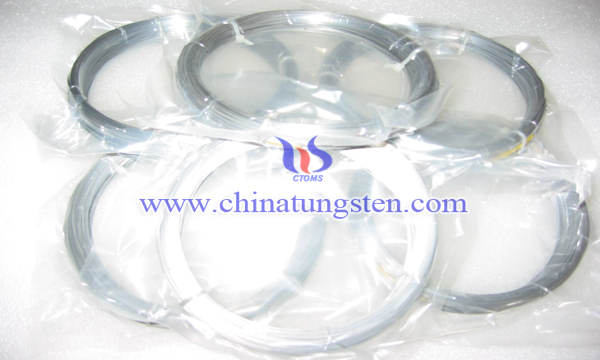

Tungsten-rhenium Alloy Filament

- Details

- Category: Tungsten Information

- Published on Sunday, 08 September 2019 22:11

Tungsten wire is the raw material for making light source materials, high temperature heaters and high temperature resistant components. The traditional production method of tungsten wire is to prepare doped tungsten oxide by adding silicon, aluminium, potassium and other elements into tungsten oxide. The doped tungsten oxide is reduced twice or once by hydrogen at 500-950 ℃, and then doped tungsten powder is obtained by hydrochloric acid, hydrofluoric acid pickling (or not pickling). The doped tungsten powder is pressed by steel mould or isostatic pressing. The doped tungsten bars were obtained by vertical sintering after moulding, and the doped tungsten bars were manufactured by rotary forging and wire drawing.

In order to solve the problems existing in the existing technology, tungsten-rhenium alloys with rhenium and potassium contents can be optimized to ensure that the material performance and performance range can meet the filament requirements. The mixing process is as follows:

A.Preparing doped tungsten-rhenium powder: mixing doped tungsten powder with ammonium rhenium rhenium rhenium solution to obtain doped tungsten-rhenium infiltrate. When mixing, the solution of ammonium rhenium rhenium rhenium acid keeps the temperature 30-50 ℃, solid-liquid weight ratio (100-150): 5; drying the infiltrate to obtain doped tungsten-rhenium powder; calculating by weight, doped tungsten-rhenium powder is 0.45%-0.55% rhenium;

B.Reduction: The doped tungsten-rhenium powder is loaded into the steel boat dish. After a hydrogen reduction furnace with 4-5 temperature zones and temperature between 500-950 ℃, the tungsten-rhenium powder is reduced to the tungsten-rhenium mixed powder once. The time of tungsten-rhenium powder passing through the whole temperature zone is about 5-5.5 hours.

C.Compression: The tungsten-rhenium mixed powder is compacted to obtain semi-finished products with certain density and strength.

D.Pre-sintering: Pre-sintering tungsten and rhenium semi-finished products, pre-sintering temperature 1150 ~1250 ℃, holding time 20 minutes to 30 minutes;

E.Vertical melting sintering: direct electrified sintering, temperature 2800-3000 ℃, holding for 30-45 minutes, to make tungsten-rhenium alloy.

In the above process, after mixing the ammonium rhenium rhenium solution with the doped tungsten powder, a doped tungsten-rhenium infiltrate is obtained. After mixing, there is no obvious water solution. No crystals can be seen in the naked eye during the drying process of the infiltrate, which prevents the segregation of liquid phase and solid phase. The doped tungsten-rhenium powders are evenly distributed, and the doped tungsten-rhenium powders are treated by subsequent reduction, compaction, pre-sintering and sintering processes. The obtained tungsten-rhenium alloys can better ensure the consistency of material properties.

- Tungsten Alloy Manufacturer & Supplier, Chinatungsten Online: www.tungsten-alloy.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com