Titanium-tungsten Alloy Oxide Nanotube Array

- Details

- Category: Tungsten Information

- Published on Wednesday, 14 August 2019 00:29

In the textile industry, azo dyes are an important raw material and a large class of organic substances that cause increasing environmental risks. These azo dyes are potentially toxic and difficult to biochemically handle. Therefore, it is of great environmental significance to take active and effective measures to treat and control azo dyes.

In recent years, photocatalytic technology, as a major advanced oxidation technology, has been widely used to treat environmental pollutants. TiO2 photocatalyst is one of the most effective catalysts due to its resistance to chemical and photo-etching, low cost, non-toxicity, high catalytic activity, strong oxidizing power and stable photochemical properties. But the biggest problem with titanium dioxide is that the band gap is too wide and can only work under ultraviolet light, which requires the addition of other elements.

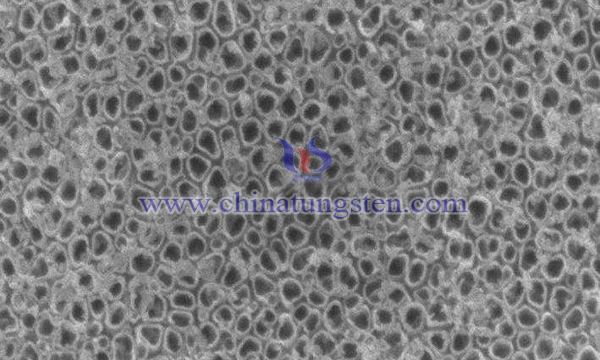

Tungsten oxide is also a main material for photocatalysts. It has been proved that titanium and tungsten have higher photocatalytic properties than single elements after synthesis. For example, some researchers have used electrochemical anodization to grow a highly ordered titanium-tungsten alloy oxide nanotube array in situ on a titanium-tungsten alloy substrate, which not only retains the excellent properties of TiO2, but also provides functionalization. The dopant material further enhances the photoelectrocatalytic performance of the TiO2 nanotubes, and the operation steps are as follows:

A Ti plate having a purity of 99.9% and a purity of 99.9% W wire were mixed in a certain ratio, and were melted in a high-temperature arc melting furnace under an argon atmosphere to obtain a titanium-tungsten alloy. It was cut into a sample of 15 × 50 × 1 mm size by a wire cutter. The exact percentage of tungsten in the alloy is 3%. The alloy sheets were polished with 100 # and 500# sandpaper in sequence, polished to a mirror surface with metallographic sandpaper, and then ultrasonically cleaned in acetone, distilled water and absolute ethanol for 15 min. The pretreated titanium-tungsten alloy sheet is used as the anode at room temperature, the platinum sheet electrode is used as the counter electrode, the electrode spacing is 1 cm, and the ethylene glycol solution containing 0.25 mol•L-1 hydrofluoric acid is used as the electrolyte solution under magnetic stirring. The titanium tungsten alloy plate was anodized at a constant potential of +60 V for 5 h. The sample was taken out and washed with double distilled water, dried in nitrogen, and then placed in a tube furnace under an oxygen atmosphere for heat treatment. The temperature was raised from room temperature to 500 ° C at a heating rate of 1 ° C / min, and then heated at 500 ° C for 2 h. The temperature was lowered to room temperature at a rate of 1 ° C/min to obtain a titanium tungsten alloy oxide nanotube array.

Compared with the traditional TiO2 nanotube array, the TiO2 nanotube array prepared by electrochemical anodization has a highly uniform W doping compared with the conventional TiO2 nanotube array, which improves the photogenerated electron-empty of the nanotube array. The separation ability of the hole enhances the photoelectrocatalytic activity, and WO3 generated by W doping in the oxidation process broadens the light absorption range of the TiO2 nanotube array, has a more uniform dopant distribution, a larger specific surface area and higher. Stability.

- Tungsten Alloy Manufacturer & Supplier, Chinatungsten Online: www.tungsten-alloy.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com