Tungsten Disulfide Applied in Nanotube

- Details

- Category: Tungsten Information

- Published on Wednesday, 19 June 2019 21:30

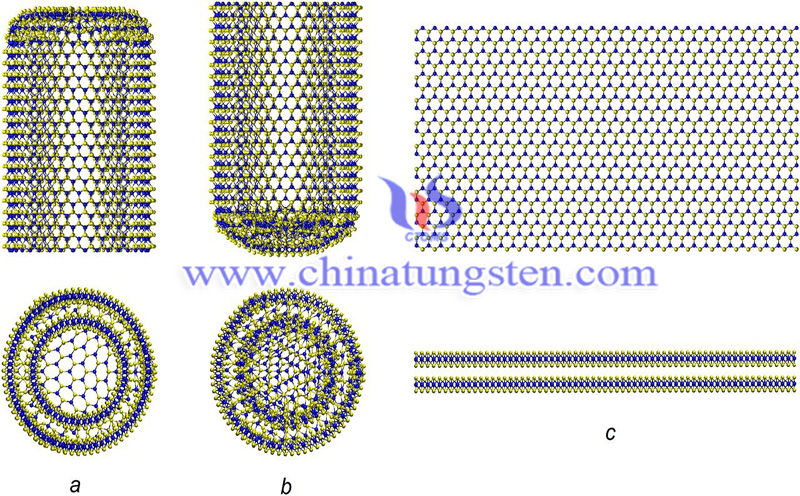

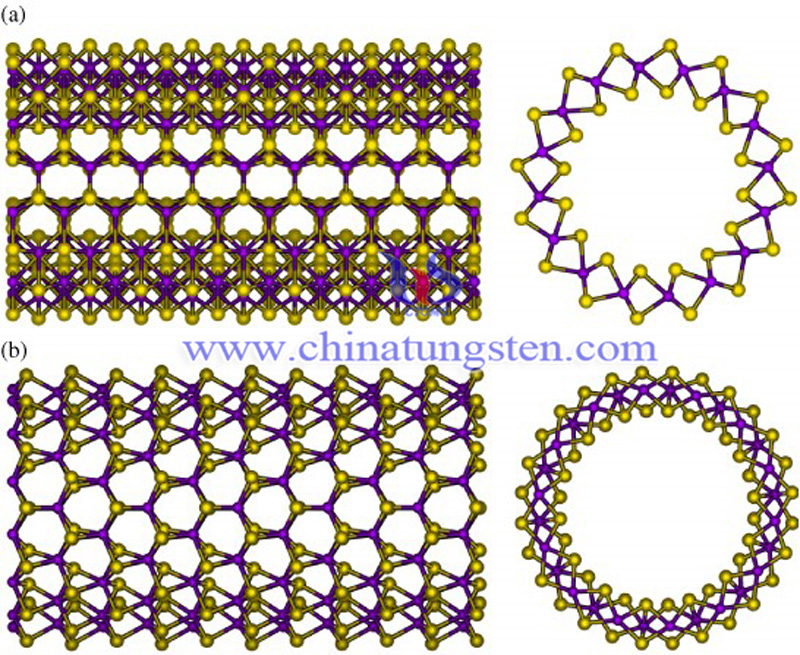

Tungsten disulfide has a layered structure related to MoS2, with W atoms situated in trigonal prismatic coordination sphere. Owing to this layered structure, WS2 forms inorganic nanotube was discovered on an example of WS2 and has been the first material which is able to form it in 1992.

This ability is related to the layered structure of WS2, and macroscopic amounts of WS2 have been produced by the methods mentioned above. WS2 nanotube has been investigated as reinforcing agents to improve the mechanical properties of polymeric nanocomposites. In a study, WS2 nanotube reinforced biodegradable polymeric nanocomposites of polypropylene fumarate (PPF) showed significant increases in the Young's modulus, compression yield strength, flexural modulus and flexural yield strength, compared to single-walled and multi-walled carbon nanotube reinforced PPF nanocomposites, suggesting that WS2 nanotube may be better reinforcing agents than carbon nanotube.

The addition of WS2 nanotube to epoxy resin improved adhesion, fracture toughness and strain energy release rate. The wear of the nanotube-reinforced epoxy is lower than that of pure epoxy. WS2 nanotube were embedded into a poly (methyl methacrylate) (PMMA) nanofiber matrix via electrospinning. The nanotube was well dispersed and aligned along fiber axis. The enhanced stiffness and toughness of PMMA fiber meshes by means of inorganic nanotube addition may have potential uses as impact-absorbing materials, e.g. for ballistic vests.

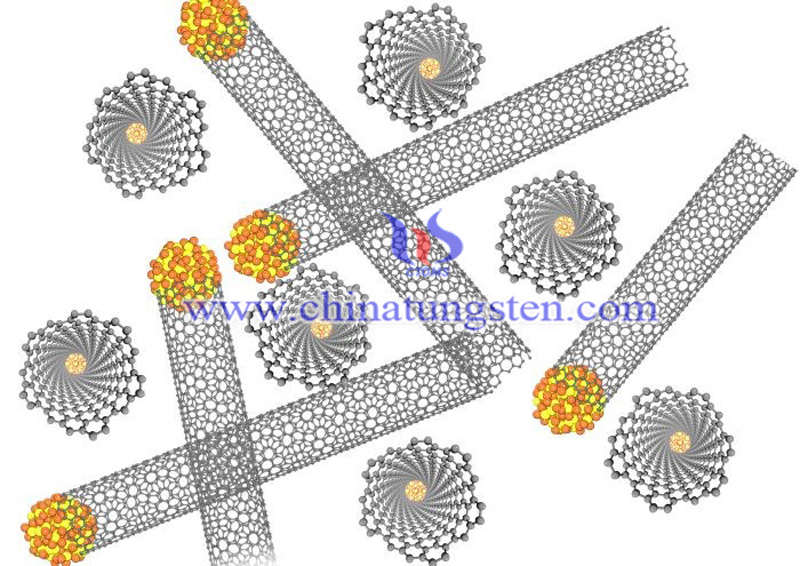

WS2 nanotube are hollow and can be filled with another material, to preserve or guide it to a desired location, or to generate new properties in the filler material which is confined within a nanometer-scale diameter. To this goal, inorganic nanotube hybrids were made by filling WS2 nanotube with molten lead, antimony or bithmuth iodide salt by a capillary wetting process, resulting in shell nanotube.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com