Mesoporous Tungsten Trioxide-Reduced Graphene Composite Photocatalyst

- Details

- Category: Tungsten Information

- Published on Saturday, 08 June 2019 10:52

With the increasing energy crisis in the world, it has become an urgent task to seek new and environmentally friendly energy sources. The use of solar photocatalytic decomposition of water to produce hydrogen or oxygen is one of the effective ways to solve the problem of energy shortage and environmental pollution. Among semiconductor photocatalysts such as TiO2, Nb2O5, ZnO and WO3, tungsten trioxide WO3 has received much attention as a typical n-type semiconductor photocatalyst.

Tungsten trioxide has the advantages of strong light absorption, high thermal stability and physical and chemical stability. It has been found that, under visible light irradiation, tungsten trioxide can act as a photocatalyst to generate oxygen by decomposing water. However, scientists also believe that nanostructured tungsten trioxide photocatalysts have shortcomings such as slow charge transport rate and low surface reactivity, which greatly limits its application.

It is well known that high catalytic activity photocatalysts require high crystallinity and a large specific surface area. Therefore, the active development of mesoporous photocatalysts has become an important direction for improving the catalytic activity of semiconductors. In addition, graphene is a new type of material with a special two-dimensional structure, and its large specific surface area and superior electrical conductivity are highly regarded. Based on these advantages, researchers have tried to combine tungsten trioxide, mesoporous materials and graphene to form a multifunctional triad photocatalyst. The process includes:

1) Preparation of mesoporous tungsten trioxide (m-WO3):

1.0 g of KIT-6 was dissolved in ethanol as a silicon-based template, stirred at 1000 rpm for 30 min, then 3.0 g of phosphotungstic acid was added to the solution, stirring was continued for 2 h, and then the solvent was evaporated to dryness at 20-30 ° C to obtain a white powder. The obtained product was calcined at 550 ° C for 5 h, the silicon substrate was removed by HF, and the product was filtered, washed with deionized water and ethanol mixture 2-3 times, filtered, and dried at 110 ° C for 1 h to obtain the product m-WO3. Ready to use;

2) Preparation of graphene oxide (GO):

1.0 g of graphite powder (<30 μm) was dispersed in 100 mL of aqueous solution. The main components of the aqueous solution were 0.5 g of NaNO3, 24.0 mL of H2SO4 and 3.0 g of KMnO4. The reaction solution was placed in an ice bath, stirred vigorously for 30 min, and then taken out at room temperature. Stirring was continued for 30 min. The reaction solution was diluted with 46 mL of deionized water. The mixture was heated to 98 ° C and stirred for 15 min. Then 10 mL of H 2 O 2 and 140 mL of H 2 O were added to the reaction system. The reaction solution was filtered and washed repeatedly with 5% HCl and deionized water. The obtained reactant was used 3-5 times, and the product was dried in a constant temperature electric blast drying oven at 80 ° C for 12 h to obtain graphene oxide (GO). Before use, a certain amount of GO was dissolved in deionized water to prepare 0.5. The solution of mgmL-1 was ultrasonically stripped for 2 h, and then centrifuged at 6000 rpm for 15 min, and the supernatant was taken for use.

3) Preparation of mesoporous tungsten trioxide-reduced graphene composite photocatalyst:

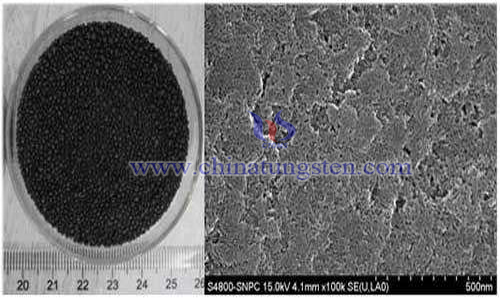

The m-WO3 prepared by the above steps and the GO solution of 0.5 mg mL-1 were mixed at a mass ratio of 1:0.02, and added to a 100 mL cylindrical glass vessel, followed by adding 50 mL of an ethanol solution to a magnetic stirrer at 1000 rpm. After treatment for 30 min, the mixture was sonicated for 30 min and placed in a dark box for 8 h under a 500 W mercury lamp. After ultraviolet light irradiation, the color of the suspension changes from taupe to black, indicating that GO is reduced to RGO, and the obtained composite material is recovered by filtration, washed with deionized water for 3-5 times, and dried at room temperature, and the product is marked as m-WO3-RGO.

The mesoporous tungsten trioxide-reduced graphene oxide composite material has large specific surface area, pores and high electrical conductivity, which effectively expands the optical response range of tungsten trioxide, solves the problem of low catalytic activity of the tungsten trioxide photocatalyst, and can be fast, Effectively decompose water to produce oxygen, the catalyst has high recycling rate and is harmless to the environment.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com