Chromium-tungsten Target Preparation by Hot Isostatic Pressing

- Details

- Category: Tungsten Information

- Published on Monday, 27 May 2019 18:00

With the continuous development of material science, the structure of materials is developing toward two-dimensional direction, which provides an important way to give full play to the potential of materials. Thin film science is a very important field for the development of new materials and devices. Target is the key material in surface coating technology. The performance of target directly affects the performance of film, and the performance of target is mainly determined by the production process of target.

Hot isostatic pressing (HIP) is a process of densifying materials in a sealed container by using high temperature and high pressure. Because the technology uses high pressure inert gas as working medium, uniform pressure is applied on the surface of the workpiece, which has the same effect on any surface of the workpiece and can improve the uniformity of internal density of the material. Due to the superiority of material preparation, hot isostatic pressing (HIP) is widely used in the process of eliminating casting defects and powder metallurgy densification. The steps to adopt such a scheme include:

1.The reduction steps of the powder: tungsten powder (average particle size 8 micron, purity: 99.99%) is fed into hydrogen at 850 ~℃ for 5 hours, and then deoxidized. The deoxidized tungsten powder with O content less than 200 ppm, i.e. the reduced tungsten powder, is prepared.

2.Powder preparation steps: the deoxidized tungsten powder and 99.95% pure chromium powder with an average particle size of 45 microns are weighed according to the weight ratio corresponding to the above atomic percentage, and the homogeneous pre-alloyed powder is prepared by high-energy ball milling process;

3.The grinding time is 4 hours; the average particle size of the pre-alloyed powder is 30-35 microns;

4.Packaging steps: the mixed pre-alloy powder is loaded into a suitable size stainless steel package;

5.Degassing steps: Place the full stainless steel ladle sleeve in degassing furnace, heating temperature 500 ℃, holding time 20 h, degassing vacuum controlled in 10-3 pa-10-4 Pa;

6.Hot isostatic pressing steps: the degassed envelope is sealed and welded and sintered in the hot isostatic pressing equipment. The holding temperature is 1450 ℃, the time is 5 hours, and the pressure is 120 MPa. Then the blank after pressing is obtained by removing the envelope.

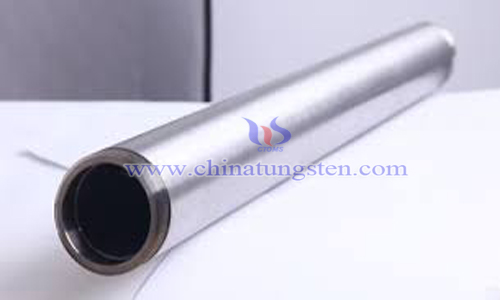

7.Processing steps: After pressing, the blank is machined according to the drawings, and the finished product target is obtained after cleaning. According to the detection, the relative density of the target is 99%, and the average grain size is less than 40 um.

By using hot isostatic pressing technology, the size of chromium-tungsten target is limited only by the size of the working room of the hot isostatic pressing equipment, so the target size can be large-scale, and the maximum size of the target can be 1701 mm. The prepared chromium-tungsten target can be used in the field of electrode contact materials and other coating fields. It can be used to prepare thin film materials with high hardness, high voltage strength, low cut-off value and can replace pure tungsten.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com