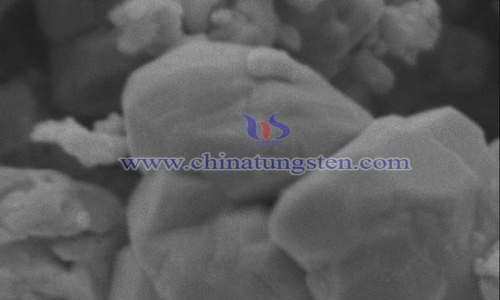

Nano-flake Tungsten Carbide Preparation

- Details

- Category: Tungsten Information

- Published on Monday, 27 May 2019 11:09

Tungsten carbide (WC) has been widely used in catalysis because of its platinum-like catalytic activity, high hardness, high thermal stability and good wear resistance. As a catalyst, WC has not only good catalytic activity for hydrogenation and dehydrogenation, but also selective catalysis for some reactions.

However, previous studies have shown that WC exhibits certain electrocatalytic activity in the fields of direct methanol oxidation, hydrogen anodization and electroreduction of aromatic nitro compounds, but its catalytic activity is not high and there is still a big gap between its practical application. Therefore, the preparation of highly active WC materials is a key problem to be solved urgently by researchers.

The structure of the catalyst has a great influence on its catalytic performance. It has been shown that the two-dimensional nanosheet can provide a large number of surface atoms and more active sites, and it is an ideal catalyst structure. The ultra-thin geometry of nanosheets facilitates the rapid transfer of loads from the interior to the surface during the catalytic reaction, thus speeding up the reaction process. The preparation process of nano-flake tungsten carbide includes:

(1)At room temperature, ammonium metatungstate and ammonium carbonate are prepared into precursor culture medium with deionized water. The precursor culture medium is added to the solution of surfactant and ethanol. After homogeneous stirring, hydroxylamine hydrochloride is added, and the pH value is adjusted to 4-8 to obtain precursor solution. The quality ratio of ammonium metatungstate and ammonium carbonate is 1:0.5-2, and the quality of the surfactant and ammonium metatungstate is good. The ratio of hydroxylamine hydrochloride to ammonium metatungstate is 0.01-0.05:1, and the quality ratio of hydroxylamine hydrochloride to ammonium metatungstate is 0.04-0.1:1.

(2)The precursor solution obtained in step (1) was hydrothermal reacted at 150-250 ℃ for 10-24 hours, then it was stationary at room temperature, the supernatant was discarded, and the sample precursor was obtained after drying.

(3)The sample precursors obtained in step (2) were carbonized in CH4 and H2 atmospheres at 600-900 ℃ to obtain nano-flake tungsten carbide.

Compared with the traditional ammonium metatungstate conversion method, the surfactant-assisted hydrothermal synthesis of nano-flake tungsten carbide can effectively avoid the agglomeration of nano-WC, thus giving full play to the effective specific surface area of nano-materials; on the other hand, it can make full use of the advantages of nano-flake materials, providing a large number of surface atoms and more reactive centers, which is beneficial to catalysis. In the process of chemical reaction, loaders are rapidly transferred from the interior to the surface, which improves the catalytic activity of nanomaterials.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com