Tungsten Trioxide Nanofibers Preparation with Core-shell Structure by Electrospinning

- Details

- Category: Tungsten Information

- Published on Tuesday, 02 April 2019 22:55

Semiconductor photocatalysts are highly praised for their stable physical and chemical properties, wide distribution on the earth, easy access, low cost and no secondary pollution. As a member of transition metal oxides, tungsten trioxide (WO3) is an indirect bandgap n-type semiconductor material with a band gap of 2.2-2.8eV. It has good absorption of visible light, so it is a very promising semiconductor photocatalyst.

Core-shell is a nano-scale orderly assembly structure formed by coating another nano-material by chemical bonds or other forces. Core-shell structure, due to its unique structural characteristics, integrates the properties of both internal and external materials and complements each other's shortcomings. It is an important research direction of morphological determinants in recent years. It has broad application prospects in catalysis, photocatalysis, batteries, gas storage and separation. At present, the preparation methods of tungsten trioxide fibers with core-shell structure include electrospinning, impregnation and chemical coating.

Electrospinning technology is a fast and simple method for preparing nanofibers. It has many advantages, such as simple manufacturing device, low spinning cost and various kinds of spinnable materials. It has great progress not only in laboratory research, but also great potential for industrialization. Therefore, it is of great industrial value and social significance to prepare tungsten trioxide nanofibers in batches by electrospinning and use them as photocatalysts.

The core-shell structure tungsten trioxide fibers are prepared by dissolving ammonium metatungstate in water and adding polyvinylpyrrolidone to adjust the ratio of raw materials to obtain the precursor solution. The precursor solution with good conductivity and viscosity is prepared by electrospinning process. After calcination, the core-shell structure tungsten trioxide with different surface morphologies is prepared. Nanofibers. Its specific operation process includes:

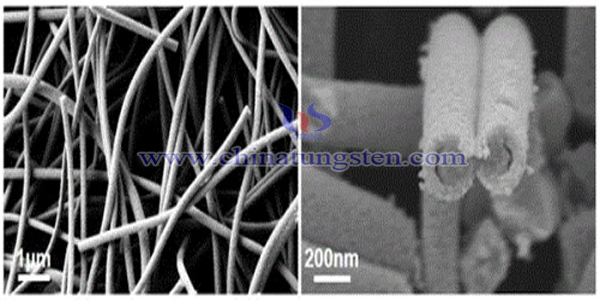

The 2.5G ammonium metatungstate hydrate was dissolved in 5 ml deionized water, and the polyvinylpyrrolidone (PVP) with molecular weight 13000 was added to 1 g. The precursor solution was obtained by stirring the solution to be uniform and transparent. Then the white cloth-like primary spun fibers were obtained by uniaxial electrospinning with voltage of 15KV, receiving distance of 12cm and driving speed of 0.01ml/min. The primary spun fibers were placed on horses. Tungsten oxide nanofibers with core-shell structure were obtained by calcining at 550 ℃, heating rate 5 / min, holding for 30 minutes, and natural cooling to room temperature.

Tungsten trioxide nanofibers with core-shell structure were prepared by electrospinning technology. The process was simple, the raw materials were easy to obtain, and water was used as solvent without any other additives. The prepared tungsten oxide had high purity, uniform diameter distribution, large aspect ratio, strong controllability of morphology, strong performance, and was easy to realize industrial mass production.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com