Nano Tungsten Carbide Spray Conversion

- Details

- Category: Tungsten Information

- Published on Thursday, 07 February 2019 21:39

Ultrafine/nanocrystalline cemented carbides overcome the contradiction between strength and toughness, have high toughness and wear resistance, and have become a hotspot in the field of cemented carbide technology in the world.

In order to produce superfine/nanocrystalline cemented carbides with excellent properties, it is very important to use high quality nano-tungsten carbide powder. At present, the main methods of preparing nano tungsten carbide are spray conversion, mechanical alloying, gas-solid reaction and sol-gel method. In this way, the spherical precursor powder prepared by spray granulation after the carbonization and reduction is still maintained by the traditional spray conversion method. The hollowed spherical shape still remains intact after the carbonization and reduction, which results in the fact that the product is not pressurized in the later stage of compaction, which causes the layering or crack of the billet, the uneven density and the unstable quality of the product, which seriously restricts the application scope of the powder.

Aiming at the problems of long preparation period, uneven particle size distribution, serious agglomeration and high cost, a new method for preparing ultrafine and nano tungsten powder, which is easy to operate, low energy consumption, uniform particle size, good dispersibility and wide application, has been proposed. The contents of the scheme are as follows:

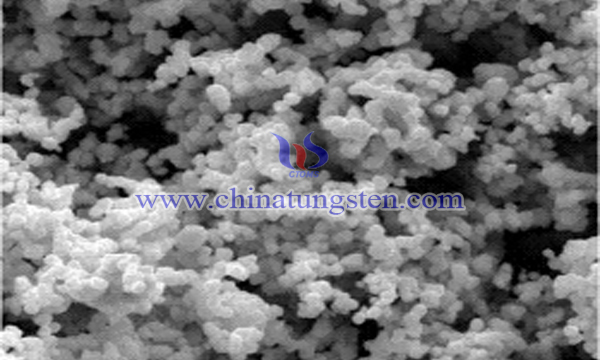

The ammonium tungstate, 5000g, was dissolved in deionized water and fully stirred and mixed evenly. The spherical particle precursor powder with an average particle size of 5.5 m was prepared by spray drying with the inlet air temperature of 140 oC and the outlet temperature of 80oC. The precursor powder was placed in a rotary furnace and heated to 600 ℃ at 6 ℃ /min heating rate. After vacuum pumping, the flow rate of hydrogen was 20. The needle-like or rod-like Purple Tungsten phase was obtained by applying the speed of 10 r/min to the furnace tube and holding for 150 min. The average diameter of the rod was 565 nm. Then the hydrogen gas was fed into the furnace tube at the rate of 50 ml/min and the temperature was 600 ℃ for 6 h. The average particle size of the ultrafine tungsten powder was 304 nm. The particle size was fine and uniform with narrow distribution.

The main characteristic of the method is to dissolve water-soluble tungsten salt in deionized water and stir it well to obtain precursor solution with uniform chemical composition and molecular weight. The spherical tungsten salt precursor powder is obtained by spray granulation, and then reduced lightly in the rotary furnace of reducing atmosphere to obtain violet tungsten. Purple Tungsten has a special surface structure and the highest chemical activity. In addition, the rod like and needle like wedge-shaped pore structure in the process of the formation of tungstic tungstate destroys the tight precursor shell morphology obtained by spray granulation and gets more loose powder, which is conducive to the reduction of hydrogen into the powder and the discharge of water vapor.

Finally, ultrafine and nano tungsten powders are prepared at different temperatures and hydrogen flow rates, and the whole process shortens the expansion of hydrogen atoms. The dispersion free path greatly shortens the reduction temperature and time.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com