Efficient Preparation of Nano Tungsten Trioxide by Vapor Deposition

- Details

- Category: Tungsten Information

- Published on Thursday, 07 February 2019 21:51

Tungsten trioxide (WO3) is an important n-type semiconductor oxide. It has many crystal structures. It has been extensively studied because of its unique physical and chemical properties. It has been applied in the fields of electrochromic, photochromic, sensing and catalysis.

The traditional preparation of nanometer tungsten trioxide powder is to place powder ammonium paratungstate on fixed furnace or rotary furnace for calcination to produce ultrafine powder by solid-state reaction, or to produce ultrafine powder by re-comminution. Although the experimental process of preparing WO3 ultrafine powder by solid-state decomposition is simple, the production cycle is long, the cost is high, the energy consumption is large, and the purity and particle size of the produced tungsten trioxide are difficult to control.

At the same time, the powders produced are easy to agglomerate and need to be crushed again. Recently, some scholars have proposed the use of vapor deposition method to precipitate nano tungsten trioxide powder, but in the research, it has also been found that the bottleneck of this technology lies in the need to collect products under high vacuum or high temperature, the production of products is very limited, and can not achieve continuous production.

In order to solve this problem, some scholars have fine-tuned the vapor deposition method again. The process is as follows:

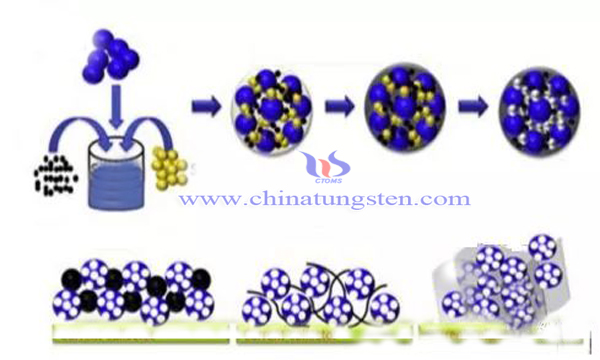

The ammonium paratungstate was evenly dispersed in the Al2O3 ceramic crucible. The crucible was placed in a quartz glass tube with an inner diameter of 30 mm. The glass tube was then placed in a tubular furnace. The tube furnace was heated to 1300 degrees C at a heating rate of 50 degrees centigrade/min. When the temperature reached 1300 degrees centigrade, the crucible was pushed to the constant temperature zone of the tubular furnace for heating, and argon gas was opened to flow rate of 2 L/min. After holding for 30 minutes, the tubular furnace was closed and blown off. Tungsten oxide powders on carbon cloth were collected in an air-cooled tube furnace at room temperature. Scanning electron microscopy (SEM) results showed that the products were nano-quasi-spherical particles with a uniform size of 200-400 nm.

In the process, carbon cloth is on the market. Carbon cloth is chosen to collect nano tungsten trioxide. One is because of its high temperature resistance, the other is to collect powder conveniently. Carbon cloth of all specifications can be used, but the suitable size of carbon cloth should be tailored according to the size of glass tube. The results show that the combination of high temperature calcination technology and vapor deposition technology, using argon as carrier gas and carbon cloth to collect powders in low temperature region, can continuously produce nano-sized tungsten trioxide particles of various shapes, and solve the problem of low yield of nano tungsten trioxide prepared by traditional vapor deposition method.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com