Mesoporous Carbon-supported Tungsten Oxide Preparation Process

- Details

- Category: Tungsten Information

- Published on Saturday, 02 February 2019 23:06

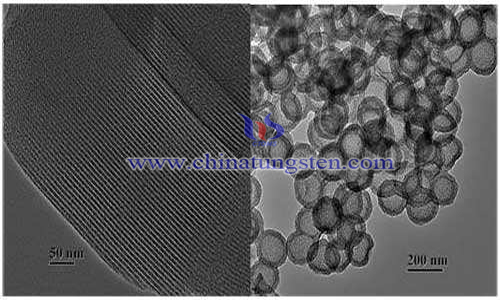

At present, tungsten functionalization of mesoporous carbon is mainly achieved by post-treatment (such as impregnation) of finished mesoporous carbon. The stability of Mesoporous Tungsten oxide/tungsten carbide obtained by this method is poor, and the loss is serious in the reaction process. Moreover, the tungsten species obtained by this method are poorly dispersed and the size distribution of tungsten particles is large, so a new process is needed to improve its shortcomings.

In order to prepare tungsten functionalized ordered mesoporous carbon materials with high performance which can meet the application requirements, it is necessary to synthesize prepolymer phenolic resin in alkaline condition. Low-order phenolic resin with tungsten functionalization was prepared by vacuum dehydration, adding tungstic acid and dehydration polymerization after heating. Modified phenolic resin and nonionic surfactant F127 were self-assembled to prepare tungsten functionalized mesoporous carbon-supported tungsten oxide materials with mesoporous structure and high dispersion. The specific operation process was as follows:

1.Add NaOH into the mixed solution of phenol and formaldehyde, raise the temperature to 70 degrees and stir for about 1 hour. Hydrochloric acid was added to the reaction system and neutralized to pH 5-7. Water-soluble resin and tungstic acid were mixed and heated to obtain tungsten modified phenolic resin. After removing the water from it by vacuum distillation, it is dissolved in ethanol and diluted to the polymer concentration of 10-40%. The mass ratio of reactants: phenol: formaldehyde: tungstic acid: = 1:0.3-3:0.05-0.

2.Configure the ethanol solution B of F127 and mix it fully with solution A. The obtained solution coating plate is stationary, and the template is removed by carbonization in inert atmosphere after self-assembly by evaporation.

3.The inert gas is nitrogen or argon, and the heating rate of carbonization is 1-5 ℃/min. Tungsten-functionalized mesoporous polymer materials were obtained at carbonization temperature of 350-600 degrees, and tungsten-functionalized mesoporous carbon materials were obtained at carbonization temperature of more than 600 degrees to 3000 degrees.

The results show that the catalysts prepared by the above process can greatly improve their catalytic performance. For example, they can be used for the decomposition of rocket launcher fuel hydrazine. The conversion rate reaches 95% at 30 degrees and 100% at 60 degrees, which can replace precious metal platinum.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com