Anode Enhancement of Mesoporous Carbon-Tungsten Coatings for Batteries

- Details

- Category: Tungsten Information

- Published on Thursday, 31 January 2019 23:41

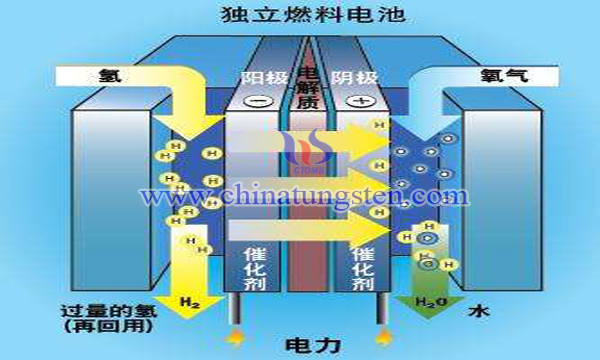

The stainless steel used for bipolar plate will be passivated in the weak acidic working environment of PEMFC. The passivation film formed slows down the further corrosion of stainless steel, but also increases the contact resistance between passivation film and carbon paper. The research shows that the carbon-based coating can be used to modify the composition, structure and surface defects of passivation film and form a compact passivation film with high corrosion resistance. And enhance the conductivity and thermal conductivity.

Therefore, mesoporous carbon-tungsten coatings for the protection of stainless steel bipolar plates in proton exchange membrane fuel cells has been prepared by some scholars, which is characterized by the following steps:

(1)Dissolve the surfactant in anhydrous ethanol and stir to form a transparent solution; then add 20% phenolic resin ethanol solution, the mass ratio of surfactant and phenolic resin is 1:5, stirring evenly.

(2)Dissolve silicotungstic acid in anhydrous ethanol, stir to get the solution and reserve it.

(3)The solution obtained by step (2) is added to the solution obtained by step (1) drop by drop, and the amount of Silicotungstic Acid corresponding to each g of surfactant is 0.025-0.20 g. The mixture is evenly stirred to obtain a yellowish transparent carbon-tungsten solution.

(4)Carbon-tungsten solution prepared by step (3) was added to stainless steel sheet drop by drop, and then dripped and leveled.

(5)The stainless steel sheet coated with solution was evaporated for at least 8 hours at 25 ℃, then thermal polymerized at 70-120 ℃ for at least 24 hours to form a yellowish coating on the surface of stainless steel. Finally, black ordered mesoporous carbon-tungsten coating was obtained by carbonization in nitrogen atmosphere.

Metal tungsten salts form nanoparticles in the carbonization process and are highly dispersed in the carbon matrix. This ensures that the ordered mesoporous structure of the coating is not destroyed. It can protect the stability of the passivation film, inhibit the anodic dissolution of stainless steel bipolar plates, reduce the influence of dissolved metal ions on the proton conductivity of the membrane of PEMFC and reduce the toxicity to the catalyst. The output power and service life of PEMFC are improved.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com