Two-dimensional Tungsten Oxide Nanosheet Preparation Method

- Details

- Category: Tungsten Information

- Published on Thursday, 31 January 2019 23:10

Tungsten oxide is an important transition metal oxide semiconductor with excellent electrochromic, photochromic and field emission properties. It has important application prospects in the fields of solar energy utilization, intelligent display, visible light photocatalysis, chemical sensing and so on.

The properties of nano-tungsten oxide are closely related to its structure, morphology and particle size. The preparation methods of nano-tungsten oxide can be roughly divided into high temperature gas phase method, mechanochemical method and wet chemical method. There are many reports about the preparation of tungsten oxide with zero-dimensional and one-dimensional nanostructures, but few reports about the preparation of tungsten oxide with two-dimensional nanosheet structure. Two-dimensional nano-tungsten oxide materials have unique electrical, optical and mechanical properties, which are different from bulk materials. Therefore, many experts and scholars have attracted in-depth study.

Recently, some scholars have published a preparation method of two-dimensional tungsten oxide nanosheets, which includes the preparation of precursor solution and hydrothermal reaction, including the following steps:

Step 1: Using tungsten powder as basic material, peroxide polytungstic acid solution was obtained by oxidation reaction of hydrogen peroxide in low temperature water bath.

Step 2: The peroxide polytungstic acid solution described in step 1 was refluxed for 5-15 h at 50-60 ℃ to obtain yellow sol.

Step 3: The yellow sol obtained in step 2 is aged at room temperature to obtain a yellow solid, which is dissolved in deionized water to obtain a solution.

Step 4: In step 3, the pH value of the solution was adjusted by hydrochloric acid or nitric acid, and then mixed with a certain amount of polyethylene glycol to obtain the precursor solution.

Step 5: The precursor solution obtained in step 4 is transferred into the reactor and reacted at 150-180 ℃ for 12-24 hours, then cooled naturally to room temperature.

Step 6: The product obtained in step 4 was filtered by vacuum, washed 2-5 times with ethanol and distilled water respectively, and then dried for 2-5 hours at 50-100 ℃ in an oven to obtain two-dimensional tungsten oxide nanosheets.

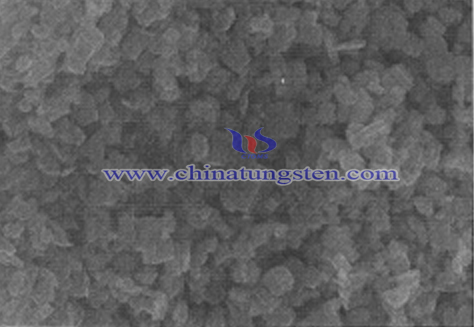

The method is low-cost, simple and easy to operate, high preparation efficiency, good repeatability and easy to industrialize. The prepared tungsten oxide nanosheets have regular morphology and uniform particle size, and can be used in visible light photocatalysis, solar cells, smart windows and gas sensors.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com