Tungsten Carbide Ceramic Heat-resistant and Wear-resistant Composites Preparation

- Details

- Category: Tungsten Information

- Published on Monday, 19 November 2018 22:07

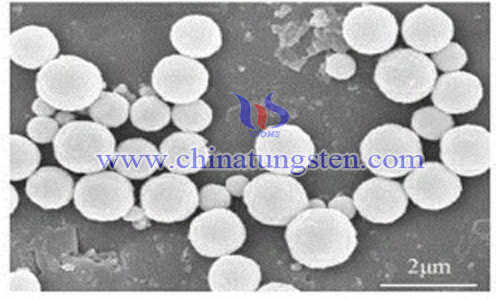

Tungsten carbide ceramics are widely used in metal processing, mining and other fields because of their high hardness, wear resistance, heat resistance, corrosion resistance and other excellent properties. However, tungsten carbide ceramics have high manufacturing cost and brittleness, and are not suitable for wearable parts with high impact force.

The waste tungsten carbide ceramics were compounded with iron-based alloys with good toughness, high strength and low price by composite preparation technology, and the surface heat-resistant and wear-resistant composite materials were prepared. The high hardness, high heat-resistant and wear-resistant tungsten carbide ceramics were obtained with high strength and good toughness, and expensive tungsten carbide could be saved. Ceramics reduce the cost of heat resistant and wear-resistant parts and expand the application scope of tungsten carbide ceramics.

In order to achieve the above objectives, some enterprises have adopted a preparation method of tungsten carbide ceramic/heat-resistant alloy-based heat-resistant and wear-resistant composite materials.

Step 1: The waste wolfram carbide ceramics (1) are cut and processed into composite reinforcement with required shape and size. YG8 wolfram carbide ceramic waste is selected and processed into wolfram carbide ceramic reinforcement with dimension 5mm x 8mm by wire cutting. Sandblasting is carried out after oil removal, and finally cleaning is carried out.

In step 2, one end of the WC ceramic reinforcement treated in step 1 is welded with iron nails (2). Vacuum brazing process is used for the welding, and high melting point foil brazing filler metal (3) with thickness of 0.2-0.5mm is used for the brazing.

Step 3, the tungsten carbide ceramic scrap (2) welded with iron nails (2) is coated with metal buffer layer by electroplating process. The tungsten carbide ceramic scrap (1) uses Co as binder. First, a layer of nickel is electroplated with a thickness of 40-80 um, and then an iron layer is electroplated with a thickness of 160-200 um.

Step 4, according to the working condition of heat resistant and wear resistant parts, the shape, size, arrangement and volume fraction of heat resistant alloy are designed. The volume fraction can be controlled from 20% to 50%. On the basis of which, the wearable part model (6) is inserted into the blind hole (7) of tungsten carbide ceramics, and the wear debris model (6) is a polystyrene foam model or stone. Wax model;

Step 5, insert the prepared tungsten carbide ceramics into the wear parts model (6), and the iron nails (2) face outwards.

Step 6, after casting, take out the castings, remove the nails, grind the working face with diamond grinding wheel, and then heat treat the workpiece. The quenching process is as follows: heating temperature 960-980 ℃, heating speed 80-100 ℃/h, heat preservation 8-10 h, air-cooling; stress relief process is as follows: heating temperature 260-300 ℃. Heat preservation 8 ~ 10h, furnace cooling, the finished product of coal mill lining tile (8).

The lost foam casting method is used. When casting, the model is placed in the sand box which can be vacuumed to ensure that the metal fully permeates the reinforcement without cold isolation or inadequate pouring. The vacuum degree is 0.02 Mpa to 0.08 Mpa, and the casting temperature is 1350 to 1450 ℃.

Practice has proved that the cost of coal mill liner using tungsten carbide ceramics/heat-resistant cast iron-based heat-resistant and wear-resistant composite material has increased by 25% compared with that of heat-resistant cast iron coal mill liner, but its heat-resistant and wear-resistant performance has increased by 8 times and has a high cost-performance ratio.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com