Silver Tungstate / Silver Bromide Composite Photocatalyst

- Details

- Category: Tungsten Information

- Published on Tuesday, 30 October 2018 22:06

In the field of pollutant degradation and energy production, semiconductor photocatalysis is one of the most promising methods. In order to find efficient photocatalysts, a large number of studies have focused on the Factors Affecting Photocatalytic activity.

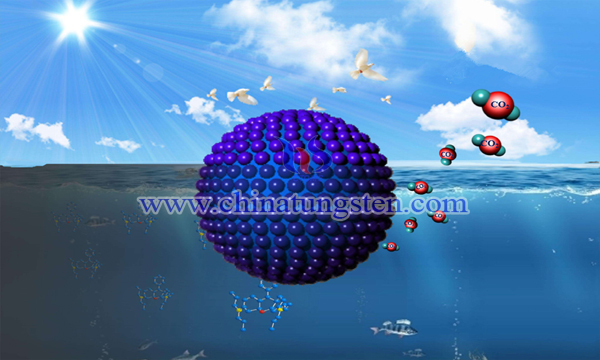

Silver bromide has the effect of photocatalyst, and the photocatalytic oxidation effect is more than ten times of the known photocatalysts. However, due to the instability of silver bromide itself, it is easy to self-corrode in photocatalysis, resulting in rapid degradation performance of the catalyst. Therefore, it is necessary to load silver bromide particles on some carriers. The material synthesized on the surface is a composite material, thereby enhancing its photocatalytic effect.

In view of the shortcomings of the existing technology, some scholars have proposed a preparation method of silver tungstate composite silver bromide photocatalyst. The method is to form a catalyst on the surface of the carrier, and the catalyst and the carrier are closely combined. The process steps are as follows:

16 mmol silver nitrate was prepared into 18 mmol / L silver nitrate solution, 8 mmol sodium tungstate was prepared into 18 mmol / L sodium tungstate solution; the above two solutions were mixed at 400 rpm to form colloidal substance, and stirred continuously for 4 hours. During the stirring process, sodium tungstate reacted with silver nitrate to form silver tungstate colloid. Silver tungstate colloid was washed four times in a semipermeable membrane bag with distilled water to remove free ions. The silver tungstate colloid was added to a sodium bromide solution with a concentration of 80mL and a concentration of 4mol/L. After soaking for 4 days, silver bromide nanoparticles were formed on the surface of silver tungstate particles. The silver bromide nanoparticles were separated by solid-liquid method. The solid was washed with deionized water three times and dried at 105 ℃. Silver tungstate complex silver bromide photocatalyst.

Silver tungstate composite silver bromide photocatalyst 0.5g was added into methyl blue wastewater with a concentration of 30mg/L at 400 mL. The decolorization rate was 98.3% after 30 min irradiation with 300 W metal halide lamp. Under the same conditions, the degradation efficiency of pure silver tungstate was only 63.1% and silver tungstate/silver bromide composite photocatalyst was visible. The effect of chemical agent is improved obviously.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com