Preparation of Hollow Porous Tungsten Oxide Spheres by Spray Drying

- Details

- Category: Tungsten Information

- Published on Tuesday, 30 October 2018 21:55

Tungsten oxide has many symmetrical n-type semiconductor materials, such as hexagonal, cubic and so on. In particular, nano-tungsten oxide has a large specific surface area, and its volume effect, surface effect, quantum size effect and macroscopic quantum tunnel effect are significant, which makes its application areas continue to expand. It can be used as solar energy absorption materials, stealth materials, photocatalytic materials and gas sensitive materials such as NOx, H2S, NH3, etc.

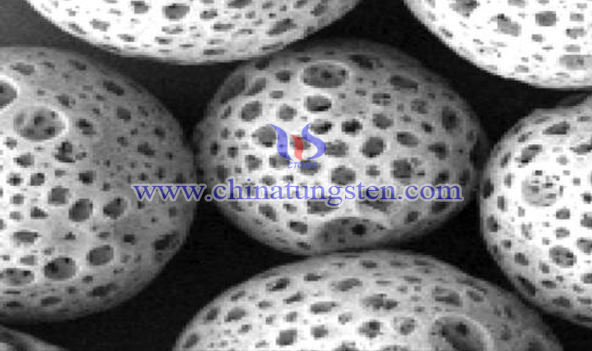

At present, the preparation methods of nano tungsten oxide photocatalyst include template method, mechanical comminution method, sol gel method and gas phase synthesis method. Recently, researchers have proposed a technology for preparing hollow porous tungsten oxide spheres, which is characterized by spray drying and heat treatment to prepare hollow porous tungsten oxide spheres.

1.Solution consisting of ammonium tungstate, ammonium metatungstate or ammonium tungstate and ammonium metatungstate with a concentration of 1 200 g/L, the mass ratio of ammonium tungstate to ammonium metatungstate in the solution consisting of ammonium tungstate and ammonium metatungstate is 1:4-4:1, the heat treatment temperature is 400-1000 ℃ and the holding time is 15-820 min.

In the growth process of nano-hollow porous tungsten oxide spheres, the growth rate of sub-crystals is slow and porous is difficult to form when the temperature is lower than 400 ℃. However, when the temperature is higher than 1000 ℃, the growth rate of sub-crystals is too fast to control the tungsten oxide nanoparticles, and the coarse tungsten oxide particles can be easily obtained. Subcrystalline growth is incomplete when holding time is less than 15 min, but when holding time is higher than 180 min, subcrystalline merger will occur and lead to the coarse tungsten oxide particles. Therefore, temperature and holding time are important control parameters of the process.

The specific implementation is to select ammonium tungstate as tungsten source and to configure a certain concentration of aqueous solution. Spray drying of EYELA SD type 1000 spray dryer of Tokyo physicochemical production in Japan is carried out. The inlet temperature is 130 degrees, the outlet temperature is 95 degrees, the blowing rate is 0.7m3/min, the spray pressure is 100kPa, and the feeding speed is 300ml/h. Fertilizer crystal GSL 1600X tube furnace decomposition, decomposition temperature of 800 ℃, holding time of 120 min, finally obtained hollow porous tungsten oxide spheres.

The combination of spray drying and heat treatment has the advantages of simple preparation equipment, short process, easy process control and high production efficiency. The hollow porous tungsten sphere prepared by this method has large specific surface area and stable performance, and is suitable for large-scale production.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com