Tungsten Carbide Montmorillonite Composite Catalyst and Its Preparation

- Details

- Category: Tungsten Information

- Published on Monday, 08 October 2018 21:12

Tungsten carbide (WC) is a kind of functional material with high hardness, good conductivity and high acid resistance. Since the discovery of platinum-like catalytic properties in the 1970s, WC has been widely used in catalytic hydrogenation, dehydrogenation, isomerization, hydrocarbon conversion and synthesis reactions in the chemical field. In the electrochemical field, WC also has a certain application prospect for hydrogen ionization and hydrogen evolution reactions.

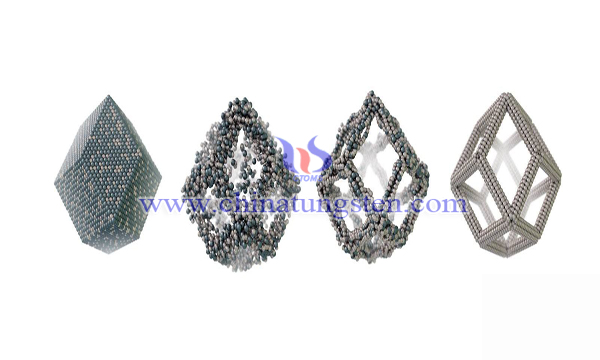

In solid-phase catalytic reaction, the particle size distribution and dispersion of the catalyst are important factors affecting the activity of the catalyst, so the preparation of highly dispersed, grain refined catalyst is one of the effective ways to improve the activity of the catalyst. The traditional method of preparation of tungsten carbide generally larger particle size, catalytic capacity is limited, so some researchers have proposed a composite scheme of tungsten carbide and montmorillonite.

Montmorillonite is a kind of natural layered silicate crystal with nanometer scale. It has strong surface electronegativity, large specific surface area and strong adsorption. The thickness of the stripped montmorillonite nanosheets is only tens of nanometers, and the aspect ratio can reach several hundred. With such nanosheets as structural units, WC can be self-assembled on its surface. The electrocatalytic activity of WC can be improved by controlling the tungsten-montmorillonite ratio and reaction conditions. The composite process of tungsten carbide / montmorillonite is as follows:

(1)Na-montmorillonite was added into 1-12 mol/L lithium chloride aqueous solution, stirred and dispersed sufficiently. In a hydrothermal reactor, the reaction was heated to 120-160 ℃ (130-140 ℃) for 12-24 h (24 h), and the precipitates were washed and centrifuged after cooling, and the peeled nano-montmorillonite tablets were dried and prepared.

(2)In step (1) the peeled montmorillonite nanosheets were mixed with tungsten hexachloride in anhydrous ethanol to obtain yellow suspension. The yellow suspension was prepared by stirring sufficiently. The precipitates were washed, centrifuged and separated, dried, grinded and prepared by reaction at 30-50 (- 30 -) for 12-24 h (preferred 24 h). Tungsten-montmorillonite precursor; the content of tungsten in the tungsten hexachloride: cation exchange capacity of peeled montmorillonite nanosheets *mass of peeled montmorillonite nanosheets) = 1-6:1, preferably 2-4:1;

(3)In step (2), the tungsten trioxide montmorillonite precursor was reduced and carbonized for 3 to 8 hours (5 to 8 hours) in the mixed atmosphere of methane and hydrogen at the rate of 1:2.3-9 of methane and hydrogen, and at the temperature of 700-900 (- 800 (- 800 -) respectively. After the reaction was completed, the methane was closed and the hydrogen was introduced for 10-30 hours. The tungsten carbide-montmorillonite composite catalyst was prepared by shutting off hydrogen for 20 min, cooling the product to room temperature under the protection of inert gas.

The tungsten carbide-montmorillonite composite catalyst and its preparation method make full use of the excellent performance of montmorillonite as support material, the catalytic performance of WC-like platinum, the control of the grain size and dispersion of WC, so as to improve the electrocatalytic performance of WC. Examples show that the composite catalyst has high electrooxidation performance for methanol and can be used as a substitute for platinum catalyst in methanol fuel cell.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com