Smooth Thin Tungsten Sheet Manufacturing in Chinese Style

- Details

- Category: Tungsten Information

- Published on Saturday, 02 June 2018 09:41

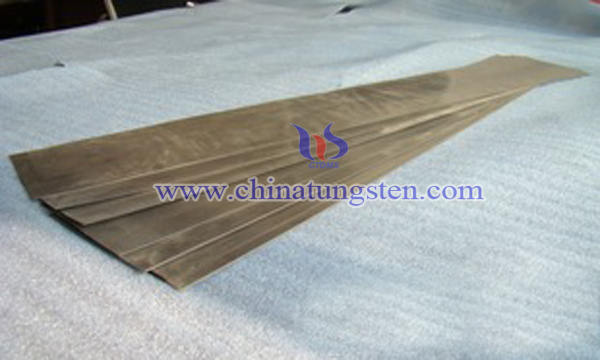

Tungsten materials have excellent thermal stability, high temperature performance and X-ray absorptive capacity. Tungsten sheet with thickness less than 0.3mm is called thin tungsten sheet. Thin tungsten sheet has excellent thermal stability, high temperature performance and X-ray absorption capacity. It has been widely applied in the fields of electrical vacuum technology and medical diagnostic equipment.

With the development of electrical vacuum technology, the market has a large demand for the thin tungsten sheet with a roughness Ra less than 0.2μm in the recent years. Domestic enterprises and scholars have developed a variety of processing methods.

(1) Tungsten slices with a thickness of 0.25mm~0.3mm were heated in high temperature oil at a temperature of 300~350°C, and then the tungsten plates were rolled more repeatedly after heating. The process rates of rolling were 10%, 10%, 9%, 8%, 8%, 7%, 7% and 7%, and the total processing rate of rolling was 44% to 50%.

(2) The tungsten sheet after multipass rolling is deoiling, then destress annealing and alkali washing.

(3) The tungsten slices after alkali washing were heated in high temperature oil at a temperature of 300~350°C, and then the tungsten slices were rolled in many ways after heating. The process rate of the rolling was 1% ~ 3%, and the tungsten slices with a thickness of 0.08mm ~ 0.10mm were obtained.

(4) The tungsten sheet after multipass rolling is deoiling, then annealed by stress, and then washed with alkali to obtain the bright tungsten sheet.

The above rolling method does not require a spray rolling lubricant, which prevents the surface roughness and surface consistency of the tungsten thin film due to the graphite layer formed by the graphite emulsion lubricant. The rolled tungsten sheet has metallic luster, good brightness, low production cost and high efficiency.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com