Nano tungsten Powder Preparation by Sol / Gel Hydrogen Reduction

- Details

- Category: Tungsten Information

- Published on Thursday, 26 April 2018 22:30

One of the main uses of nano tungsten powder is to prepare ultra-fine tungsten carbide, but it has also become an indispensable material in many high-tech fields. For example, the micro electronics industry, fine chemical industry, surface technology, aerospace industry, nuclear industry and other fields also have great demand for nano tungsten powder.

At present, only a few countries in the world can produce nano tungsten powder and nano tungsten base alloy, and the price is high. The homogeneity of nano tungsten powder produced by some factories in China is low and contains tungsten oxide, which severely limits the application of tungsten materials in China.

In order to break the international market of nano tungsten powder and related products controlled by a small number of foreign manufacturers, Chinese scholars have proposed a preparation method of nano tungsten powder with independent intellectual property rights. The scheme is to prepare nano tungsten powder using sol-gel hydrogen reduction method. The water-soluble tungsten metal salt and citric acid are dissolved together in distilled water, hydrolyzed, pH-adjusted, complexed, and polycondensed to form a gel, and then dried and calcined to form an oxide of tungsten, and then an argon-hydrogen gas mixture is used. The protective reduction produces nano-sized tungsten powder. Its main content is as follows:

Dosage: the distilled water of 500mL is added to 198.82g ammonium tungstate, 334.33g citric acid and 37.56g oxalic acid niobium; then the good ammonium tungstate, oxalate niobium, and citric acid are poured into the distilled water containing distilled water and stirred with a stirrer, stirring at a speed of 120 rpm, and dissolving ammonium tungstate, oxalate niobium, and citric acid. Then the pH value of the solution was detected. When pH < 6, the pH=6.5 was adjusted by ammonia. Then, the thermostatic heater 3 is opened, the temperature is set at 80 degrees centigrade, and at the same time, the mixture is continuously stirred, forming a wet gel with complex structure through evaporation and condensation.

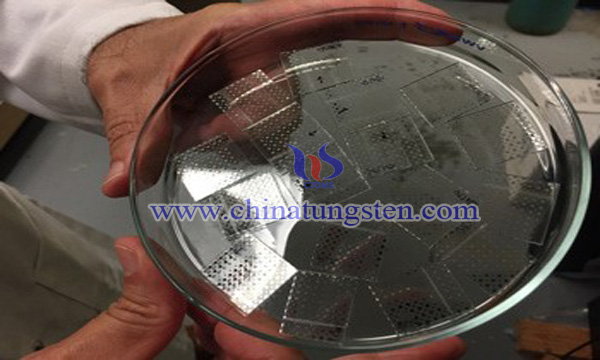

When the wet gel becomes a viscous paste, it is taken out into the evaporating dish. The wet gel and the evaporating dish are placed in a drying oven and dried. The temperature is set to 105 ℃. After drying for 32 hours, the water is taken off. It becomes a porous xerogel.

The xerogel is placed in a crucible and calcined 120min in muffle furnace. The calcination temperature is 450 degrees. The precursor is formed after calcining. The precursor is placed in the crucible 11, and the crucible is placed in the central position of the furnace cavity in the quartz tube 10 of the vacuum furnace, with a number of porous silicon refractory plug 6, and the quartz tube at both ends of the vacuum sealing sleeve with the trachea 7. When the air pressure is reduced to about 0.5Pa, when the air pressure is reduced to about 0.5Pa, then the air inlet pipe is put into argon, the air is squeezed for about 5 minutes with argon, and then the hydrogen is added, the flow ratio of argon and hydrogen is 3:1, the flow rate of argon is 120ml/min, and the flow rate of hydrogen is 40ml/min. Set the sintering temperature, sintering reduction time 60H, and then turn on the control switch.

The preparation of nanometer tungsten powder by sol / gel hydrogen reduction method has solved some problems in traditional preparation methods. The experimental operation is simple and easy to operate. It does not need too many complicated equipment. The raw material is easy to buy in the market. It only needs one hydrogen reduction and no carbon residue. It can adjust the production quantity according to the size of the furnace chamber of the actual vacuum furnace, and greatly save the cost.

- Tungsten Powder Manufacturer & Supplier, Chinatungsten Online: tungsten-powder.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com