Foreign Spherical Tungsten Carbide Powder Preparation Method

- Details

- Category: Tungsten Information

- Published on Sunday, 22 April 2018 14:59

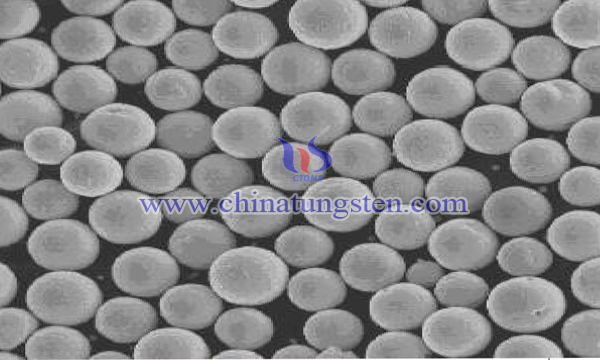

Spherical tungsten carbide powder is an important thermal spray material and is playing an increasingly important role in various industries such as electronic information, metallurgy, and machinery.

Foreign countries are studying the preparation of spherical tungsten carbide powders by some special techniques. Mainly four kinds as follows:

(1) Centrifugal rotation method: Using tungsten powder as raw material, mix evenly with carbon black in disc refiner. The mixture is continuously supplied to a water-cooled copper crucible, and the molten cast tungsten carbide is prepared by melting it with an arc. The liquid through the nozzle in the crucible of cast tungsten carbide sprayed to the surface water or concave turret rotating tube. According to the product's particle size, it needs to rotate at a certain speed and be dispersed into droplets by centrifugal force, then let the droplets shrink into spherical particles by themselves. Tungsten carbide pellets freely fall from the rotating table or rotating tube to the bottom of the water-cooled furnace chamber.

(2) Rotary atomizing method: Tungsten, tungsten carbide, return material, and carbon black are blended into a blend based on the carbon content of the cast eutectic spot of tungsten carbide. The propeller of the screw conveyor continuously pushes the mixture to the exit of the mix material. The arc generated by the electrode forms a high temperature above 3000°C in the melting chamber and the mixture melts in a short time. The decomposition and carbon-absorbing reactions take place to form molten WC and W2C. The melt continuously dropped under gravity onto a high-speed rotating circular table with a water-cooled jacket. Relying on centrifugal force, the melt is dispersed into many small droplets, splashes along the tangential direction, cools and crystallizes at an extremely fast rate, and finally falls into the cooling storage chamber.

(3) Induction or resistance heating spheroidization method: Induction heating or resistance heating spheroidizing technology uses conventional cast tungsten carbide as raw material. High-temperature melting and rapid condensing spheroidization are realized on ultra-high-temperature spheroidizing equipment. Multi-grain grade spherical cast tungsten carbide powder is prepared by controlling temperature, raw material particle size, particle size composition, feeding amount, feeding mode and screening. The entire preparation process needs to be carried out under the protection of inert gas.

(4) Gas atomization method: Tungsten powder and tungsten carbide powder are used as raw materials, and the ingredients are mixed according to a certain amount of carbon; then they are added to the high-temperature smelting gas atomization furnace at a certain speed by pelletizing. After melting at a high temperature of nearly 3000°C, the melt enters the high-temperature atomization zone. Under the strong impact of the gas under high pressure, small droplets are formed. The droplets enter the cooling zone, and rapidly cooled to a spherical tungsten carbide powder depending on the surface tension.

The application of centrifugal rotation method is more common, the temperature of the atomization method is higher, the production efficiency is low, and the process flow of the induction heating spheronization method is long, and the gas atomization method has higher requirements for the equipment.

- Tungsten Powder Manufacturer & Supplier, Chinatungsten Online: tungsten-powder.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com