Tungsten Diselenide Preparation

- Details

- Category: Tungsten Information

- Published on Thursday, 08 March 2018 18:36

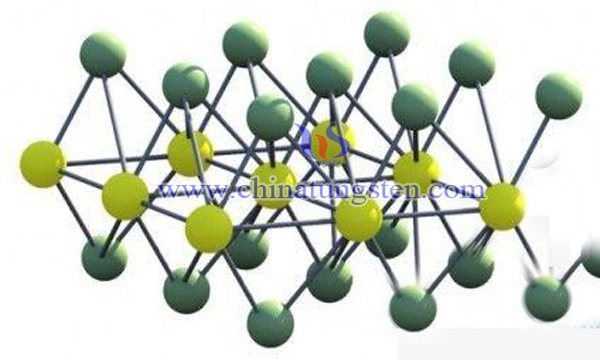

Tungsten diselenide (WSe2) is a kind of semiconductor material with a graphite-like layered structure. It is composed of closely packed Se-W-Se hexagonal crystals, and is based on van der Waals force to form a single layer of two-dimensional material. The WSe2 film has a forbidden band width of 1-2eV and a high visible light absorption efficiency. It can be used as an absorbing layer and photoelectrochemical electrode material for solar cells.

As with tungsten disulfide, the preparation of tungsten diselenide is also more cumbersome, the more common practice is the physical gas phase method. However, the cost of the tungsten diselenide production method is longer and the time is longer. Therefore, the preparation method of the tungsten diselenide still needs improvement.

Aiming at the defects existing in the method for preparing vertical substrate growth tungsten diselenide nano-sheet film materials, some scholars have proposed a simple, rapid and low-cost method for preparing vertical substrate growth tungsten diselenide nano-sheet films. The main contents are as follows:

1.After the substrate is placed in a magnetron sputtering chamber, the magnetron sputtering chamber is evacuated to 1.0×10 −3 Pa or less, argon gas is used as a working gas, and a tungsten target is used as a sputtering source. The pressure of the working gas is controlled by DC magnetron sputtering in the range of 0.9Pa to 10.0Pa, and tungsten thin films are produced on the surface of the substrate.

2.Selenium powder is added to the open container, a substrate with a tungsten film on the surface is covered on the open container, and the tungsten film on the surface of the substrate is placed facing the selenium powder in the open container; Then, the open container is placed in a closed container placed under a vacuum of less than 10 Pa and a temperature of 550 ℃ to 1000 ℃, so that tungsten diselenide can be obtained.

This method mainly controls the microstructure of the precursor tungsten thin film by controlling the process conditions of the DC magnetron sputtering tungsten thin film, then the vertical selenide tungsten thin film was efficiently prepared by the rapid selenization technique to meet the application requirements of hydrogen production and electrocatalysis.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com