Preparation of Composite Photocatalyst with Copper Doped Violet Tungsten Oxide

- Details

- Category: Tungsten Information

- Published on Sunday, 25 February 2018 15:14

Tungsten catalyst in a large number of materials, with special surface structure of violet tungsten oxide, oxygen defect structure of high chemical activity and high concentration, and in the ultraviolet has a high degree of absorption, at the same time, research shows that copper as doping elements can improve the catalyst in the visible light response range. Therefore, the selection of copper doped violet tungsten as a photocatalytic material has a good application prospect.

The methods of preparing photocatalyst materials are mainly sol-gel method, hydrothermal method, precipitation method, microemulsion method, gas phase method and so on. The hydrothermal method is the most common method, and the hydrothermal process for the preparation of copper doped violet tungsten photocatalyst is roughly as follows.

1.According to the stoichiometry and copper nitrate 0.01mol, ammonium metatungstate 0.01mol, ammonium nitrate 0.24mol, urea 0.1mol, the selection of raw materials according to a certain proportion of tungsten and copper nitrate solution, the molar ratio of the source is 0.3 ~ 1, the molar ratio of ammonium nitrate and tungsten source was 12~36; auxiliary agent and the molar ratio of tungsten source for 5~15.

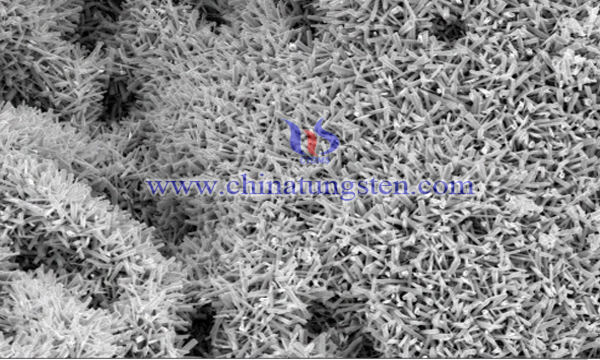

2.The raw material powder is dissolved in the appropriate deionized water until it is completely dissolved. It is heated at constant temperature of 200 degrees, and the solution is evaporated to dry. Then it will undergo intense redox reaction in dozens of seconds to form copper doped violet tungsten powder. The obtained powder is nanoscale, the diameter is 50 ~ 150nm, the length is 1~3 m, the concentration is 1g/L, and the copper doped violet tungsten composite photocatalyst is finished.

Hydrothermal preparation of copper doped violet tungsten oxide, the process is short, cost, simple process, suitable for large-scale production, and through the process of the ratio of stable morphology and crystal control of the final product, to ensure that the copper ion into the violet ungsten lattice, rather than forming a mixture of copper oxide and violet tungsten oxide, composite the influence of electron and hole, achieve the optimal catalytic effect.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com