Wettability of Sintered Liquid Phase

- Details

- Category: Tungsten Information

- Published on Tuesday, 20 February 2018 18:58

Tungsten carbide is a typical multicomponent liquid phase sintering. It is sintered at a temperature below the melting point of the main component of the alloy (WC), of which the low melting point component (Co) melts and forms a low melting eutectic phase with WC.

Whether liquid phase sintering can be successfully completed (densification is thorough) depends on three basic conditions related to the nature of liquid phase: wettability, solubility and quantity of liquid phase. The wettability has a great influence on the densification, microstructure and properties of tungsten carbide.

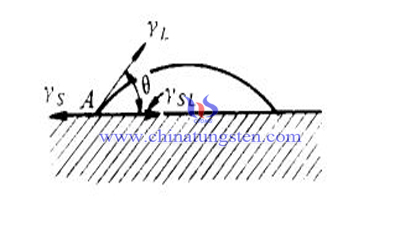

The good wettability of liquid to solid particles is one of the important conditions for liquid phase sintering. Wettability refers to the ability or tendency of a liquid to spread on a solid surface. It is determined by the surface tension of solid, liquid phase (specific surface energy) γs, γl and interfacial tension (interfacial energy) of the two phases (interface energy) of γsl. When the liquid phase is wetting the solid phase, the thermodynamic equation of the equilibrium at the contact point A is:

γs=γsl+γlcosθ(1)

Where θ-- wetting angle(0°- 180°).

The smaller the wetting angle, the better the wettability of the solid.

1.θ=0°. The liquid phase completely moistens the solid particles, and the liquid spread on the solid surface, which was the most ideal liquid phase sintering condition. When the temperature is around 1500℃, the wetting angle of the liquid Co and WC is 0 degrees, and the wetting angle of the nickel is equal to zero and the iron is poor.

2.0°<θ<90°. The liquid can moisten the solid, and the smaller the theta, the better the wettability.

3.90°<θ. The liquid cannot moisten the solid; the solid particles push the liquid phase into the sintered body, and the anti-sintering phenomenon occurs. At the beginning of the sintering, the liquid phase, even if it is produced, will quickly run out of the sinter in vitro, called exudation. In this way, most of the low melt components in the sintered alloy will be lost and the sintering densification process cannot be successfully completed.

4.θ=180°. Completely non-wetting, the liquid condenses into a small ball on the surface of the solid. Only with full or partial wetting conditions can the liquid phase penetrate into the micropores, cracks and even grain between the particles.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com