Preparation of Tungsten Trioxide by Chemical Precipitation and Vapor Deposition

- Details

- Category: Tungsten Information

- Published on Tuesday, 06 February 2018 16:31

Chemical precipitation is a method of preparation of tungsten trioxide. Chemical precipitation is the use of chemical reactions in the liquid phase to synthesize nano-tungsten trioxide powder. That is, adding the required amount of precipitating agent to the reaction liquid system to obtain the precursor precipitate, and converting the precursor into the final nano-tungsten oxide powder material through the drying and calcining processes. Some scholars have synthesized zinc oxide powder by chemical precipitation method.

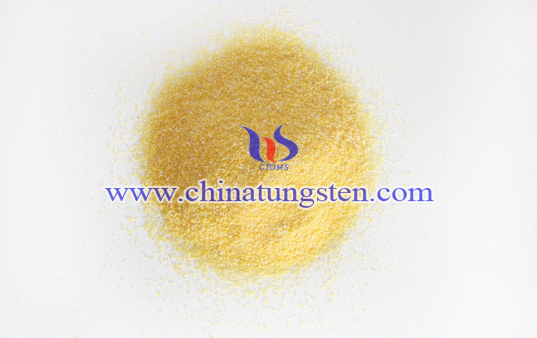

Chemical precipitation Preparation of tungsten trioxide specific steps: sodium tungstate and tin tungstate solution mixed. The solution was then slowly added dropwise to boiling dilute sulfuric acid to precipitate the resulting precipitate. The precipitate is then washed, dried and calcined to give the final product, tungsten trioxide. The main advantage of chemical precipitation is that the reaction process is simple and the cost is low for industrial production. However, its disadvantage is that the resulting tungsten trioxide particles tend to have larger particles.

Preparation of tungsten trioxide by vapor deposition of the principle is: the reaction of raw materials for heat treatment, so that reflects the raw material from solid to gas. At the same time reactants in the gaseous state may occur physical changes or chemical reactions. After cooling the system can be obtained in the nano-tungsten trioxide powder. The tungsten trioxide powder obtained by the method has the characteristics of high purity, good dispersion and narrow particle size distribution in the nature. The vapor deposition method can be subdivided into vacuum deposition method on flowing oil surface, sputtering source method, gas evaporation method, chemical vapor reaction method and metal vapor synthesis method. Here is a simple example to illustrate. Place the tungsten trioxide powder in a quartz tube and place a tungsten plate in the quartz tube as a base. The tungsten trioxide powder is heated and purged with nitrogen. After a period of time on the tungsten film has been a purple product, after analysis shows that the product is W18O49. Vapor deposition method due to the higher requirements of synthetic equipment and harsh reaction conditions have been subject to certain restrictions.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com