Tungsten Alumina Ceramic Heating Substrate Preparation

- Details

- Category: Tungsten Information

- Published on Thursday, 01 February 2018 22:06

Ceramic heating substrate is a new generation of new heating element developed in recent years. Because it has the characteristics of environmental protection, high reliability and long life, it is replacing the commonly used PTC heating element containing lead. It has wide market prospect at home and abroad. Therefore, the research on the production technology of high temperature alumina ceramic heating substrate has been paid more and more attention.

Aqueous tape casting process using water as solvent instead of organic solvent, because the water molecules are polar molecules, and binder, plasticizer and dispersant are organic additives, and exist the problem of compatibility between water molecules, so in the choice of additives, organic matter to water soluble or capable of forming a stable emulsion at the water to ensure uniform and stable slurry obtained. Therefore, it is the key to make suitable slurry in the casting process of water system.

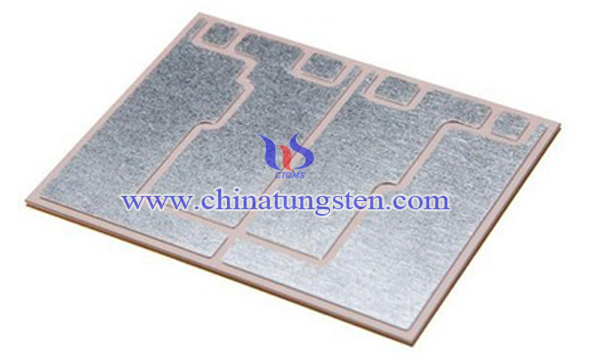

For this reason, a Chinese scholar invented a problem in the course of water tape casting, such as poor wettability of solvent (water) to powder, difficulty in removing foam from slurry, slow evaporation and long drying time, and poor adhesion between ceramic and metal layer after sintering. A method of preparing a tungsten alumina ceramic heating substrate which can significantly improve the qualified rate and efficiency of sintering. The concrete steps are as follows:

1) Preparation of ceramic premix and tungsten slurry

The distilled water, Magnesium Oxide, titanium oxide, dispersant and plasticizer were mixed, then alumina powder was added, and the pH value of ammonia water was adjusted to make ceramic premix. Tungsten powder, bonded phase and organic carrier are mixed and mixed in a vibrating ball mill. The average size of the slurry is less than 0.8 u m, and the tungsten slurry is made.

2) Ball milling

The ceramic premixed material was grinded and then mixed with the binder to make the average particle size less than 0.3 um. After adding defoamers, vacuum degassing was applied to make ceramic slurry.

3) Casting molding

Casting the prepared ceramic slurry on a casting machine and drying, and slicing the alumina raw ceramic sheet;

4) Silk screen printing

The paste made of tungsten by screen printing technique was uniformly deposited on the surface of alumina ceramics to students;

5) Sintering

With the birth of alumina ceramic printing film static, drying and discharging processing, sintering, to obtain a sintered substrate;

6) Nickel plating

Using the electroless nickel plating process, the sintered substrate is kept in the bath containing nickel sulfate, and a layer of nickel is formed on the surface of the sintered substrate, that is to say, the tungsten containing alumina ceramic heating substrate is obtained.

The preparation method adopts the system of production of tungsten containing alumina ceramic heating substrate testing its density is greater than or equal to 3.8g/cm3 by Archimedes method; test the tensile strength is more than 150MPa with electronic universal testing; Air tightness ≤ 1 × 10-10Pa · m3 / s; Insulation resistance tester with insulation resistance ≥5 × 109Ω; Room temperature resistance of 70 ~ 200Ω; Fully meet the electronics industry on the ceramic metal products.

It can be seen that tungsten containing ceramic heating substrate has good performance, good quality, high yield and low production cost. This method improves the overall performance and sintering qualification rate of ceramic heating substrate through reasonable sizing and proper process route. The preparation method is simple and easy to operate, and is suitable for large-scale production. The product can fully meet the requirements of the electronic industry for ceramic metallized products. The ceramic heating substrate of the invention can be widely used in the fields of household appliances, medical sterilizers, electric heating equipment and so on.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com