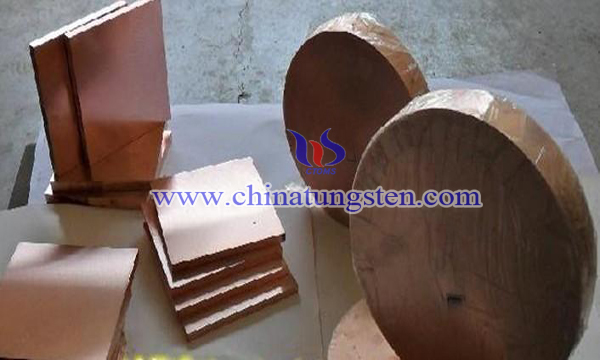

Tungsten Copper Alloy Preparation by Casting Method

- Details

- Category: Tungsten Information

- Published on Thursday, 01 February 2018 18:14

Tungsten copper alloy composite material combines the advantages of two kinds of elements W and Cu, has low thermal expansion coefficient, good conductivity, good thermal conductivity and good arc erosion resistance, in mechanical processing, electrical engineering and electronic information field is widely used as electrical contact materials, electrode materials and electronic packaging materials.

Tape casting process is a resin sheet extruded by extruder and extruded through the slot die, so that the melt is tightly attached to the cooling roller, and the sheet is made through stretching, trimming and coiling. The method of preparing tungsten copper sheet or plate by tape casting is studied. The copper coated tungsten composite powder is selected as raw material to prepare tape casting slurry. Then the cast tape is then cast, sintered, pressed, infiltrated and sintered, and surface treated, and then tungsten copper sheet or plate can be obtained.

1.The preparation process of casting slurry is as follows: adding solvent, dispersant, binder and plasticizer to copper clad tungsten composite powder, stirring in magnetic stirrer for 1 ~ 2H, and rotating speed controlled at 300 ~ 600r/min, obtaining casting slurry.

2.The specific operation process is as follows: 2, casting the casting slurry into the trough casting machine, control of blade height is 1.5 ~ 2mm, the casting speed is 30 ~ 60cm/min for casting, then dried by casting slab.

3.The specific operation process of the gumming sintering is as follows:the cast slab placed in a quartz boat or graphite boat in a protective atmosphere or vacuum sintering furnace row glue sintering. First row at a temperature of 500 ℃ ~ 600 ℃ incubated 0.5 to 1 hour, and then slowly heated to 1300 ℃ ~ 1400 ℃ sintering 1 ~ 2 hours, then, it is cooled down to the room temperature in protective atmosphere or vacuum.

4.The specific operation process of compaction is as follows: after pouring and pre sintering cast strip or slab into steel mold or plate, press it on the press simply, pressing pressure is controlled at 300 ~ 600MPa, keep pressure 1 ~ 1.5min, and get pressed blank or plate.

5.The specific operation process of infiltration and sintering is as follows: the pressed blanks or plates pressed are placed in the internal protective atmosphere or vacuum sintering furnace of quartz ark or graphite boat. At the same time, copper material is placed on the surface of pressed billet or plate. The copper content is 150% of the copper content of copper coated tungsten composite powder and the copper content of tungsten copper sheet or plate prepared. Control the temperature at 1300 ~ 1400 ℃, holding 1 ~ 1.5 hours for infiltration sintering, followed by cooling in a protective atmosphere or in a vacuum oven to room temperature.

6.The specific operation process of surface treatment is as follows: remove the floating copper from the surface of the pressed blanks or plates after infiltrating and sintering on the mechanical processing equipment or lapping machine, then polish or grind them.

Copper and tungsten composite powders are selected as raw materials, which can solve the problem of copper segregation in the process of powder sintering and make copper uniformly distributed around the tungsten matrix. It fundamentally avoids the difficulty of controlling the uniformity of mixture in traditional powder metallurgy process, and lays a solid foundation for subsequent infiltration and sintering, and even the final homogeneity of tungsten copper sheet.

- Tungsten Alloy Manufacturer & Supplier, Chinatungsten Online: www.tungsten-alloy.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com