Proton Exchange Membrane Fuel Cell Tungsten Carbide / Platinum Composite Catalytic Material

- Details

- Category: Tungsten Information

- Published on Sunday, 07 January 2018 16:51

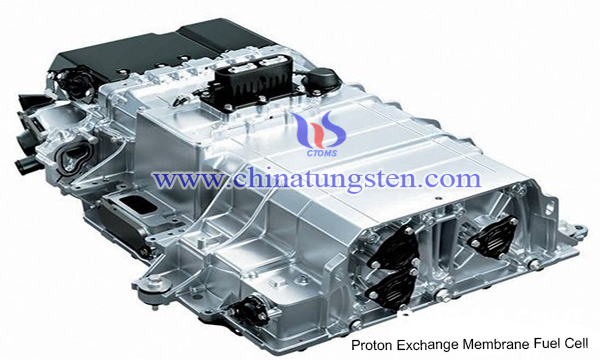

Fuel cell is a proton exchange membrane fuel cell (PEMFC), which directly uses methanol water or hydrogen as fuel to generate electricity from the source. It has the characteristics of rapid start-up at low temperature, clean fuel and environmental protection, and simple structure of battery. It is an environmentally friendly and efficient new energy.

Up to now, the biggest bottleneck of fuel cell development is the problem of its catalyst. The catalyst is mainly based on platinum Pt, but Pt is expensive, and it is easily poisoned by the intermediate products of methanol oxidation, thus affecting the commercialization process of DMFC.

Carbon black is used as the carrier in most of the existing PEMFC technologies, and Pt particles are loaded to the surface of carbon black, and the supported Pt/C catalyst is obtained. The carbon carrier has a large specific surface area, which can greatly reduce the use of Pt for precious metals and reduce the overall cost of the battery. However, the problem of oxidation and sintering is also an important problem perplex researchers. The working environment of fuel cell is relatively unique, with higher temperature (50-90 degrees), higher water content, higher acidity (pH < 1) and higher potential (0.6-1.2V). Under such adverse conditions, the electrochemical oxidation of carbon is more likely to occur in a long term, especially in the case of high Pt content. Moreover, when the battery operates under unconventional conditions, such as bad startup or variable load, it is possible that the reverse polarity will occur, which will cause irreversible influence on the battery due to the extreme oxidation of carbon.

Tungsten carbide has been paid much attention by scholars because of its catalytic properties similar to platinum. This paper introduces a preparation method of tungsten carbide / platinum composite catalytic material for proton exchange membrane fuel cell. The preparation method is simple and no complex equipment is needed.

The research shows that the tungsten carbide / platinum composite catalyst material prepared by this method shows better oxidation tolerance than the conventional platinum catalyst. When the battery fuel or oxidant is prone to exhaust gas, the tungsten carbide /Pt catalyst with strong oxidation resistance can effectively avoid serious performance loss caused by unexpected conditions such as reverse polarity. The substitution is strong, it can greatly reduce the amount of platinum, the preparation process is also simple, without complex equipment, it has a good market application prospects.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com