Commonly Used Tungsten Carbide

- Details

- Category: Tungsten Information

- Published on Saturday, 06 January 2018 16:50

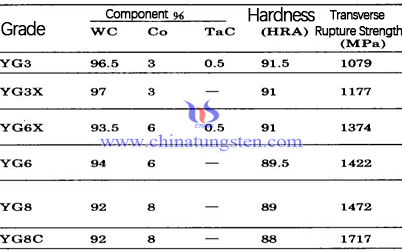

Tungsten carbide has many advantages, such as high hardness, good wear resistance, high resistance to deformation and so on. So, it is suitable to be used as a powder metallurgy mold. In China, the most commonly used tungsten carbide for mould is WC-Co system tungsten carbide of which the drilling content is low to medium (6-20). Especially, YG8 and YG15 serials are the most widely used.

Powder metallurgy die is a kind of cold working mold, of which the working temperature is at or not higher than 200℃. It bears great pressure, lateral pressure and certain impact force when working. The female die must have high strength and toughness as the stress and strain will be produced under the action of lateral pressure. At the same time, it must have high hardness and wear resistance as it is constantly rubbed with the processed metal powder. The die and mandrel must have these properties and, of course, have enough toughness.

When the grain degree of tungsten carbide is the same and the hardness of the alloy increases, the wear resistance is increased, the strength is slightly reduced, and the toughness is obviously worse. As for the low drilling grade YG alloy for mould, it has high wear resistance and smaller impact toughness.

The wear resistance is reduced, and the impact toughness is increased with the increase of cobalt content in the alloy. Therefore, if the wear resistance is high and the punching pressure is small, the alloy with lower drilling content can be selected, otherwise, the alloy with higher drilling content can be selected. And standard parts die bear great pressure, so YG15, YG20 and YG25 tungsten carbide with high impact toughness are selected.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com