Thermal Debinding Defect: Debinding Deformation

- Details

- Category: Tungsten Information

- Published on Thursday, 26 October 2017 23:31

Thermal debinding is the most commonly used degreasing method. Its principle is the volatilization and cracking of organic molecules. It is often used as the final degreasing method of two step degreasing.

Degreasing rate is very slow, time-consuming, generally spend more than ten hours or even a few days, only suitable for the production of relatively small precision ceramic parts. The technology of thermal debinding of cemented carbide is simple, low cost, no special equipment, less investment.

In the process of thermal debinding, the defects of the body are often caused by improper process control or other reasons. The common hard aggregate defects include degreasing deformation, degreasing crack, bubbling, warping, delamination, decarburization, etc. Among them, degreasing deformation is the most common thermal debinding defect, which can be eliminated or alleviated by component and process control.

1. Causes of Degreasing Deformation

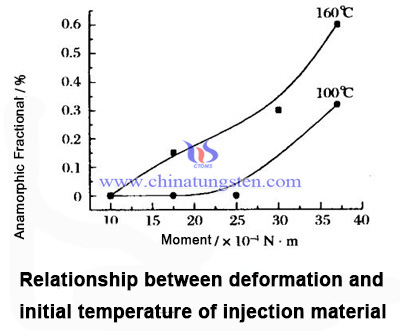

The debinding deformation of cemented carbides is mainly due to the softening of binder components during thermal debinding, and the viscous flow and deformation of the body easily occur under the action of gravity and thermal stress.

2. Prevention and Solution

2.1 Selecting the powders with larger particle friction. The raw material of cemented carbide is irregular polygonal shape, and the friction coefficient between particles is relatively fixed. By increasing the powder contact area, the friction can be increased.

For cemented carbide powder, the finer the particle is, the larger the contact area between particles is. Therefore, in order to improve the debinding deformation, the powder with finer particle size can be used without affecting the properties of cemented carbide products.

2.2 Increasing powder loading as much as possible. It can reduce the deformation effect by increasing the powder loading and reducing the proportion of binder components.

2.3 Choosing a binder with a better shape preserving multi component system.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com