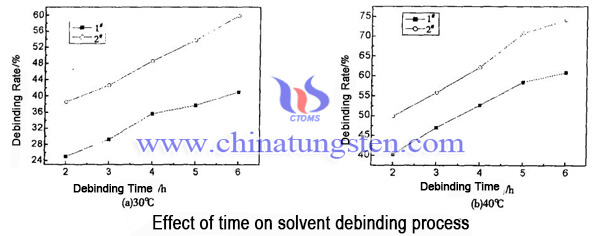

Effect of Time on Solvent Debinding Process

- Details

- Category: Tungsten Information

- Published on Tuesday, 24 October 2017 23:12

Injection molding technology has been widely used in the field of cemented carbide production as a result of its excellent characteristics. In the field of cemented carbide production, the two-step degreasing process is most commonly used solvent degreasing + thermal debinding.

Solvent degreasing is generally the first step and the most important step in degreasing process. The quality of solvent degreasing directly affects the quality of cemented carbide products. The degreasing time of solvent degreasing has a direct influence on the degreasing rate, and is related to the production efficiency and production cost of the whole injection molding, so the influence of the study on degreasing process is crucial.

1, Overall Trend of Impact

With the increase of degreasing time, the removal rate of binder increased, while the rate of increase gradually slowed down. Finally, it tends to be constant. The reason is that with the increase of time, the removal rate of binder increases, and the concentration of binder in solution increases, and the concentration difference between the binder and the solution decreases. As shown in the following picture.

2, Periodical Trend of Impact

The immersion time of binder injection blank in solvent has a great influence on the amount of adhesive removal. In the early stage of degreasing, the binder concentration in the debinding and solvent is quite different, and it is easy for the binder to diffuse and dissolve from the injection blank to the solution. At the same time, the binder removal rate is faster, and the binder concentration in solvent increases.

As the time goes on, the concentration difference between the solvent and the solid body decreases, and the system enters the dissolution control stage, and the concentration difference becomes the main factor affecting the reaction rate. The decrease of binder concentration in the debinding and solvent resulted in the dissolution of the binder and the diffusion rate in the solvent, and the debinding rate slowed down gradually.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com