Influencing Factors of Catalytic Degreasing Rate

- Details

- Category: Tungsten Information

- Published on Sunday, 22 October 2017 00:20

There are many influencing factors that affect the catalytic degreasing rate during injection molding. The most common factors are binder component, catalytic gas flow rate, degreasing time and degreasing temperature.

Formula of degreasing rate is as follows:

Wd%=(Wi-W)/Wi×100

Where:

Wi – weight (g) of the original binder in the injection blank;

W - weight (g) of the residual binder in the degreased blank.

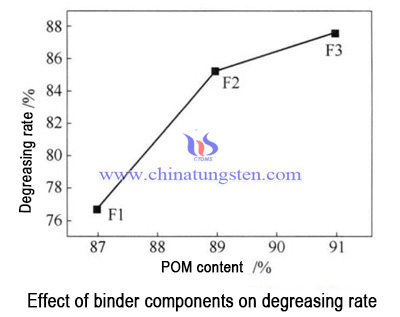

1, Effect of binder components on catalytic debinding rate (as shown below)

In the binder of injection molding, it is necessary to contain components that can degrade rapidly in a specific acidic atmosphere. At the same time, other auxiliary components need to be added to ensure the strength of the resin after removing the resin.

The more the content of the polyacetal resin in the catalytic degreasing binder is, the higher the removal rate of the binder in the injection blank is, but the worse the shape preservation of the skim blank is. So, the component needs a balance.

2, Effect of catalytic gas flow rate on catalytic debinding rate

In the process of Catalytic Debinding, high speed inert gas streams (nitrogen, argon, helium and their mixture) are usually introduced into the debinding furnace to accelerate the diffusion of small molecules and regulate the debinding rate.

The degreasing rate can be controlled by controlling the concentration of the catalyst. Moreover, with the decrease of the inert gas flow rate, the catalyst concentration in the degreasing zone increases, and the overall debinding rate increases. Therefore, the flow rate of inert gas should be controlled within a moderate range.

And, the flow of acid gas cannot be too large. For example, if the HNO3 concentration is too large, the catalytic gas will have a certain degree of corrosion, causing harm to the powder and equipment.

3. Effect of degreasing time on catalytic debinding rate

With the increase of Catalytic Debinding time, the debinding amount of injection molded blank increases, and the increasing trend of debinding amount becomes stable. The change trend is different from degreasing time when degreasing temperature is different.

4. Effect of degreasing temperature on Catalytic Debinding rate

The catalytic debinding rate increases with the increase of debinding temperature. POM is gradually decomposed from the end under acidic conditions.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com