Water Extraction Degreasing

- Details

- Category: Tungsten Information

- Published on Saturday, 14 October 2017 21:50

Based on solvent extraction degreasing process, a new degreasing process was developed after improvement, which is so called water extraction degreasing. The binder during the process can be divided into two parts.

One is soluble in water, and the most widely used water soluble polymers are polyethylene glycol (PEG), polyethylene oxide (PEO) and agarose derived from cellulose and cellulose. The other part is insoluble in water, including poly methyl methacrylate (PMMA), polyvinyl butyral (PVB) resin or cellulose acetate butyrate (CAB) etc..

Water Extraction Degreasing Process:

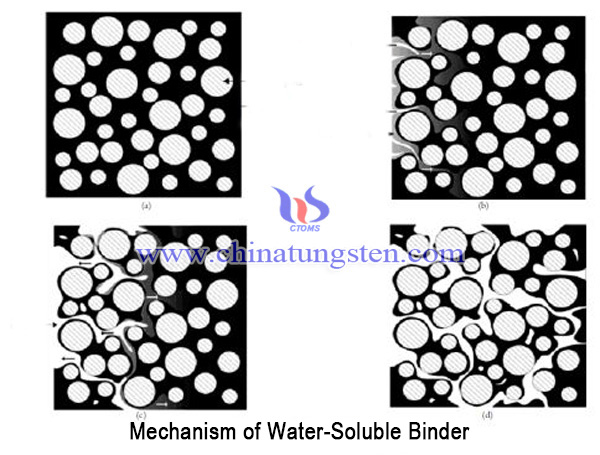

The removal mechanism of water-soluble binder in the solid body is shown below. Firstly, the preform is ceramic powder and binder, and the powder particles are filled with continuous binder between the two-phase system. When the body is immersed in hot water at 40 -60 ℃, it expands rapidly because of heating. Water molecules diffuse to the surface of the body and form a swelling body with adhesive molecules. The adhesive on the surface of the solid body dissolves and forms tiny voids.

As degreasing proceeds, the water molecules diffuse into the inner part of the body with the voids, swelling with the internal binder molecules and leaving more voids with the dissolution of the internal binder. The contact surface between water and binder is larger and larger, and the degreasing rate is improved.

Finally, after 2-3 h of degreasing, the interconnected porous channels are formed. And the porosity inside the body increases obviously. These water-insoluble binders support the green body, forming many channels inside the body, and these channels can also become the channels of heat discharged from the body after the water-insoluble binder.

Characteristics of Water Extraction Degreasing:

Compared with organic solvent degreasing, water degreasing has larger degreasing rate, and it will not damage the health of human or pollute the environment. As the water-soluble binders absorb water, the special equipment is needed for the storage and transportation of MIM feed. Moreover, the polymer which is compatible with water-soluble part of water soluble binder (such as polyethylene glycol) is very little, and it is easy to swell during mixing, and the mixing time is long.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com