The Properties and Features of Poly Tungsten

- Details

- Category: Tungsten Information

- Published on Thursday, 11 June 2015 18:46

- Written by wenjing

- Hits: 463

The properties and features of poly tungsten:

High density: ≥11.34 g/cm3

Perfect radiation shielding performance: Tungsten has comparable radiation shielding ability as lead but is much healthier than lead. To date, many manufacturers, especially those in medical industry, are trying to replace lead radiation shielding products with Poly Tungsten products.

Good flexibility and excellent workability: Poly Tungsten sheets can be cut or holed with household scissors and formed into shapes with various curved surfaces.

Healthy and environmentally friendly: Poly Tungsten is made of non-toxic & recyclable materials and produces no pollution to the environment.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Polished Tungsten Tube

- Details

- Category: Tungsten Information

- Published on Thursday, 11 June 2015 18:05

- Written by Yahong

- Hits: 420

Polished tungsten tube refers to semi-finished surface of pure tungsten tube after polishing products. Outer surface finish, wall caustic pure tungsten tube, the surface smooth, bright, shiny metal pan, the inner surface of the outer surface of the light is better. Pure tungsten tube diameter range is very wide, up to 100 mm, diameter size can also be controlled to 12 mm in length no restrictions, it can be customized according to user requirements. Usually taken pure tungsten tube through the use of pure tungsten rod system. Given its high temperature resistance, high melting point characteristics, pure tungsten tube can be used to protect its internal wire, the wire can also be introduced into the lumen to its high temperature gas or liquid.

Under standard conditions, unbound hard and rare metals, tungsten is a natural compound found on Earth. In 1781, a new element has been identified, first isolated in 1783 in the metal. Its important ores include wolframite and scheelite. Freedom notable feature is its excellent corrosion resistance, especially in the second highest of all the elements that most carbon it's all non-alloyed metal melting point later on. Equally striking is the high density of its 19.3 times that of water, comparable uranium and gold, much higher than the small amount of impurities of lead (approximately 1.7-fold), tungsten is often brittle and hard, making it difficult to work. However, very pure tungsten, though still difficult, more toughness, and can be cut with a hacksaw hard steel.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Sputtering Gas Volume Influence Tungsten Oxide Nano Films

- Details

- Category: Tungsten Information

- Published on Thursday, 11 June 2015 18:03

- Written by xiaoshan

- Hits: 429

Using reactive sputtering method producing tungsten trioxide nano films found the average particle size diameter is less than 100nm. The grains size of the tungsten trioxide (WO3) nano films are related to magnetic irradiation conditions and treatment temperature. After studied showed that sputtering gas volume and proportion play an important role at increase gas sensing property of nano WO3 film.

By XPS analysis, although proportions of mixed sputtering gas (O2 / Ar) is different, but the combination of W4f7 / 2 and Ols energy unchanged, namely 35.5eV and 530.6eV. And WO3 film stoichiometric not change, but when the O2 partial pressure is difference the WO3 nano-film microstructure will be a great change, this phenomenon can be explained by reduction aggregate. That is when O2 partial pressure increases the crystal grain size becomes smaller. However, if the O2 partial pressure is greater than 50% then it will result porosity reduced, thereby reducing the sensitivity of original, indicating that the optimum sputtering mixing ratio is 1: 1. So the sputtering mixed gas (O2 / Ar) ratio is 1: 1 which using DC reactive magnetron sputtering to produce WO3 nano film has best gas sensing properties.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Radiation Shielding in Logging-While-Drilling

- Details

- Category: Tungsten Information

- Published on Thursday, 11 June 2015 18:05

- Written by wenjing

- Hits: 463

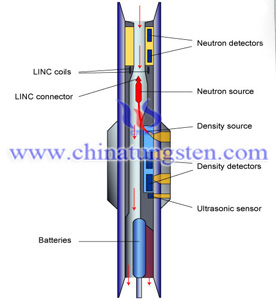

The logging-while-drilling tool provides real-time apparent neutron porosity, formation bulk density and photoelectric factor data to characterize formation porosity and lithology while drilling. Due to its high density, excellent absorption behaviour against radiation and environmental friendly characteristics, tungsten alloy can be widely used to produce tungsten radiation shield in density detector of logging-while-drilling.

The radioactive sources are safely contained in the drill collar and are connected to each other by a tungsten radiation shielding that allows fishing by wire line through the drill pipe.These nuclear measurements are borehole compensated for improved accuracy. 360-degree images of density and porosity result from the rotation of the tungsten density detector.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Melt Infiltration Method Prepares Tungsten Copper Rod

- Details

- Category: Tungsten Information

- Published on Thursday, 11 June 2015 17:59

- Written by limei

- Hits: 462

Tungsten has a melting point 3410 °, the boiling point of copper 2 567 ℃. Because copper is much higher than the melting point of tungsten and tungsten and copper boiling immiscible, thus tungsten copper alloy rod casting method can not be used to the system. Melt infiltration method prepares tungsten copper rod can improve the compactness of tungsten copper rod and other material properties.

Principle of melt infiltration method prepares tungsten copper rod is that the use of a capillary force, the low melting point metal wetting liquid filling certain density and strength of the porous matrix skeleton. The molten metal flow to fill the gap along the porous particles of tungsten skeleton pore, resulting in denser materials, greatly improve the toughness of tungsten copper rods.

There are some drawbacks of melt infiltration method prepares tungsten copper rod: Because liquefied copper tungsten skeleton pore capillary action alone infiltration densification therefore slower, less densification. Copper solidified coarse and distribution is not uniform, but will make high temperature sintering tungsten particles grew up together, forming a thick uneven tissue.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com