A Preparation method of Nanometer Ta-W powder for 3D printing

- Details

- Category: Tungsten Information

- Published on Monday, 30 July 2018 18:32

- Written by yuntao

- Hits: 598

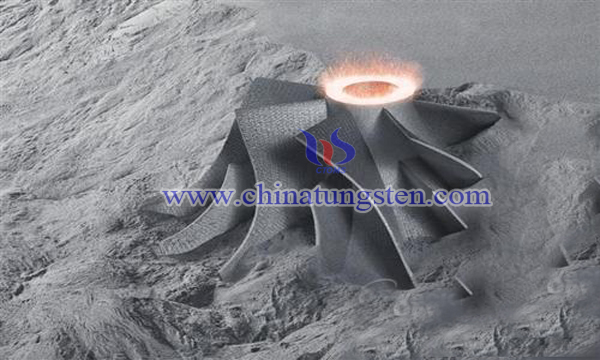

Tantalum-tungsten (Ta-W) alloy is widely used due to its high density, high melting point, high ductility, modulus of elasticity, good processing properties, high temperature strength, high corrosion resistance, weldability and low brittle-to-ductile transition temperature (BDTT). It is used in aerospace, defense, military, chemical, and nuclear industries. With the development of 3D printing technology, Ta-W powder has also become one of the main 3D printing materials, mainly used for printing complex or miniature Ta-W alloys, which also puts higher requirements on the performance of the powder.

Read more: A Preparation method of Nanometer Ta-W powder for 3D printing

A Method to Recover Tungsten and Nickel from Waste Nickel-Tungsten Catalysts

- Details

- Category: Tungsten Information

- Published on Monday, 30 July 2018 18:29

- Written by yuntao

- Hits: 769

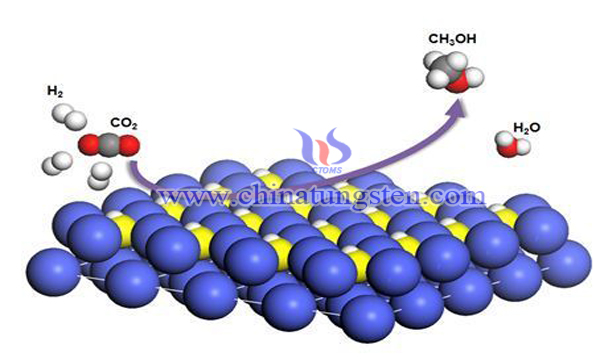

Nickel-tungsten catalysts are widely used in hydrotreating and hydrocracking. The main components are about 25% tungsten trioxide, 2% nickel oxide, 50% alumina, 5% silica, and a small amount of iron, vanadium and other substances. Waste nickel-tungsten catalysts contain metals such as tungsten and nickel. If they are recycled, they will generate huge economic benefits and avoid environmental pollution caused by the waste of nickel-tungsten catalysts.

Read more: A Method to Recover Tungsten and Nickel from Waste Nickel-Tungsten Catalysts

The Direct Reduction Carbonization Method to Prepare Ultra-Fine WC Powder

- Details

- Category: Tungsten Information

- Published on Monday, 30 July 2018 18:18

- Written by yuntao

- Hits: 513

Tungsten carbide (WC) is the main raw material for the production of cemented alloy. The main production method is one-step method and two-step method. At present, the main method for producing WC powder is two-step method: Firstly reducing the tungsten oxide to tungsten powder with hydrogen. Then, tungsten powder is carbonized to form WC powder at a high temperature. In the production practice, the method is not suitable for producing ultrafine WC powder.

Read more: The Direct Reduction Carbonization Method to Prepare Ultra-Fine WC Powder

An Acid Process to Concentrate Oxidized Tungsten-Molybdenum Ore

- Details

- Category: Tungsten Information

- Published on Monday, 30 July 2018 18:24

- Written by yuntao

- Hits: 837

In recent years, the improvement of the metallurgy and the improvement of the concentration capacity of the oxidized tungsten-molybdenum ore have been greatly improved. For example, Gansu, Qinghai, Xinjiang, Inner Mongolia and other provinces now, has the ability to have a froth float on tungsten-molybdenum ore with a tungsten trioxide content of 3 to 8%, and a molybdenum content of 2.5 to 12.5%; The Guangdong and Guangxi regions have the ability to have a froth floatation on tungsten-molybdenum ore containing 20 to 45% of tungsten trioxide and 10 to 25% of molybdenum.

Read more: An Acid Process to Concentrate Oxidized Tungsten-Molybdenum Ore

Hardness Testing Methods of Tungsten Carbide Button

- Details

- Category: Tungsten Information

- Published on Monday, 30 July 2018 18:15

- Written by yating

- Hits: 1350

Tungsten Carbide Button has a series of excellent properties, such as high hardness, abrasion resistance, good strength and toughness, heat resistance, corrosion resistance and so on. Meanwhile, the properties of high hardness and abrasion resistance keep the tungsten carbide button in shape basically at 500℃ and maintain the high hardness at 1000℃.

Read more: Hardness Testing Methods of Tungsten Carbide Button

sales@chinatungsten.com

sales@chinatungsten.com