Secondary Carbonization Method to Produce Tungsten Carbide

- Details

- Category: Tungsten Information

- Published on Friday, 03 August 2018 18:14

- Written by yuntao

- Hits: 530

Tungsten carbide is an important raw material for the production of cemented carbide. The preparation technology of tungsten carbide is various, and the preparation of tungsten carbide powder from tungsten powder is the most widely used one.

Read more: Secondary Carbonization Method to Produce Tungsten Carbide

Carbide-Cobalt-Chromium Thermal Spray Powder

- Details

- Category: Tungsten Information

- Published on Friday, 03 August 2018 18:06

- Written by yuntao

- Hits: 515

Tungsten carbide belongs to the ceramic phase and has the advantages of high melting point, high hardness, high electrical and thermal conductivity, stable chemical properties, etc. It is an ideal material for preparing wear-resistant and corrosion-resistant coatings. However, due to the high melting point and high hardness of tungsten carbide (WC), the adhesion between the sprayed tungsten carbide particles and the substrate is poor, and oxidation occurs when air temperature raise. Therefore, the pure tungsten carbide powder is rarely used alone as a thermal spray powder material, and it is usually required to add a metal or alloy such as Co, Ni, Ni-Cr. The binder phase is used as a sintered powder or a coated powder for thermal spraying.

A Separation Method of Tungsten-Tin Ore

- Details

- Category: Tungsten Information

- Published on Friday, 03 August 2018 11:31

- Written by yuntao

- Hits: 647

China is the world's largest producer of tungsten and a major producer of tin. Southern Yunnan and Western Yunnan of China are the main origin of tungsten-tin paragenic ore. Since it is difficult to apply the conventional methods (gravity concentration, froth flotation or magnetic separation) to separate the tungsten-tin ore, thousands of tons of them have been wasted. When tungsten exists as an impurity in tin concentrate, it is not only wasted, but also affects the cost of tin metallurgy and the quality of tin products; while tin exists in tungsten products as impurities, even if the amount is very small, the quality of tungsten products has been adversely affected.

Tungsten Carbide Mining Button Process

- Details

- Category: Tungsten Information

- Published on Friday, 03 August 2018 18:05

- Written by yating

- Hits: 503

During the brazing of tungsten carbide mining button, the size of welding gap is the key factor that will affect the density and strength of weld line. If the gap is too narrow, it will hinder the inflow of the solder; if the gap is too wide, it will destroy capillary action so that the solder can not fill the gap.

Bronze-type Niobium Tungsten Oxide

- Details

- Category: Tungsten Information

- Published on Thursday, 02 August 2018 19:09

- Written by Cristina

- Hits: 795

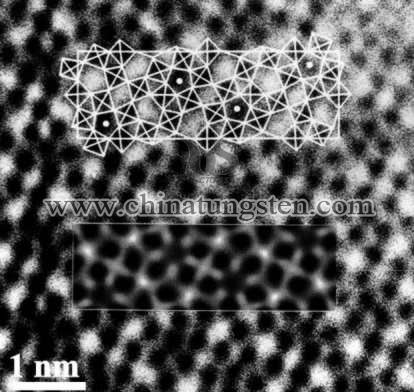

In the pseudo-binary system Nb2O5/WO3, Nb8W9O47, crystallizing in a threefold superstructure of the tetragonal tungsten bronze (TTB) type, represents the most stable compound. The superstructure arises from a systematic occupation of a part of the pentagonal channels with metal-oxygen strings (see figure).

sales@chinatungsten.com

sales@chinatungsten.com