Tungsten-Based Plasma Facing Components

- Details

- Category: Tungsten Information

- Published on Thursday, 02 August 2018 18:15

- Written by yuntao

- Hits: 507

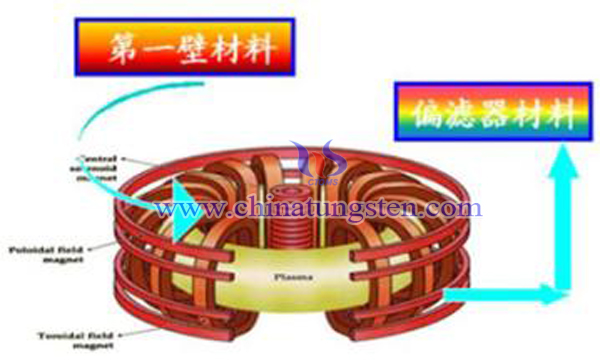

Tungsten materials are considered to be plasma facing components (PFC) for the preparation of the International Thermonuclear Experimental Reactor (ITER) due to its high melting point, high sputtering threshold, high thermal conductivity, low vapor pressure, and low hydrogen isotope retention.

Almonty Industries to Improve Tungsten Concentrate Output at Panasqueira Mine in Portugal

- Details

- Category: Tungsten Information

- Published on Thursday, 02 August 2018 11:22

- Written by Cristina

- Hits: 615

Almonty Industries Inc. is pleased to announce that the ore sorting equipment has arrived at its Panasqueira mine in Portugal. The equipment was released by customs last week and during the 23rd and 24th of July 2018, the entire installation arrived at the mine.

Read more: Almonty Industries to Improve Tungsten Concentrate Output at Panasqueira Mine in Portugal

Environmentally Friendly Tungsten-Based Catalysts

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 August 2018 18:14

- Written by yuntao

- Hits: 720

In order to implement the Montreal Protocol to protect the Earth's ozone layer, countries around the world have introduced zero-ODP values of hydrofluorocarbons (HFCs) and hydrofluoroolefins (HFOs) to phase out chlorofluorocarbons (CFCs) and hydrofluorides Chlorocarbons (HCFCs). At present, HFCs and HFOs have been widely used as refrigerants, cleaning agents, foaming agents, fire extinguishing agents, etchants, and etc.

Read more: Environmentally Friendly Tungsten-Based Catalysts

Niobium Tungsten Oxides Help Make Faster-charging Batteries

- Details

- Category: Tungsten Information

- Published on Thursday, 02 August 2018 11:20

- Written by Cristina

- Hits: 786

Is there an alternative to nanostructuring electrode materials to speed up ionic diffusion in lithium-ion batteries and so increase their maximum power output and charging rates? Yes, according researchers at the University of Cambridge in the UK, who have shown that two complex niobium tungsten oxides can intercalate large amounts of lithium even when the oxides are microns in size.

Read more: Niobium Tungsten Oxides Help Make Faster-charging Batteries

High-Efficiency Method for Separating Tungsten and Molybdenum

- Details

- Category: Tungsten Information

- Published on Wednesday, 01 August 2018 17:38

- Written by yuntao

- Hits: 700

With the continuous exploitation of high-quality tungsten-molybdenum ore resources, complex tungsten-molybdenum symbiotic mineral resources are gradually being consumed. However, the impurity content in tungsten product or molybdenum product seriously affects its performance. The most difficult impurity element to remove from tungsten products is molybdenum, while for molybdenum products, tungsten is the most difficult to separate. In order to improve the performance of tungsten and molybdenum products, separation of tungsten and molybdenum is necessary. Therefore, in order to efficiently utilize these tungsten-molybdenum symbiotic mineral resources, the separation of tungsten and molybdenum is the key.

Read more: High-Efficiency Method for Separating Tungsten and Molybdenum

sales@chinatungsten.com

sales@chinatungsten.com