Tungsten Carbide/Titanium Dioxide Composite Catalyst

- Details

- Category: Tungsten Information

- Published on Sunday, 06 January 2019 16:04

- Written by meiwei

- Hits: 483

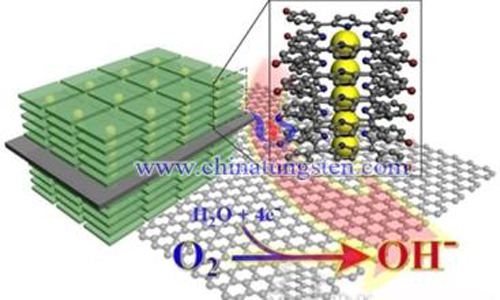

Tungsten carbide can catalyze hydrogenation, hydrogenolysis and reforming of alkanes. At the same time, nano-tungsten carbide has high electrochemical activity and good catalytic effect in low temperature acidic medium. It is acid-resistant, high temperature-resistant and CO-poisoning-resistant. It also shows catalytic oxidation performance for hydrogen, water and methanol oxidation.

Read more: Tungsten Carbide/Titanium Dioxide Composite Catalyst

Ultrafine Tungsten-Copper Composite Powder Preparation by New Technology

- Details

- Category: Tungsten Information

- Published on Sunday, 06 January 2019 15:50

- Written by meiwei

- Hits: 471

Tungsten-copper composites have the advantages of tungsten and copper, high density, low coefficient of thermal expansion, good electrical and thermal conductivity, and are widely used as electrical contact materials, electrode materials and microwave power device substrates in the modern microelectronics information industry. The electronic packaging material such as the connecting member and the heat dissipating component and the heat sink material can be used as the guide material of the electromagnetic gun and the armor-piercing medicinal cover of the armor-piercing projectile.

Read more: Ultrafine Tungsten-Copper Composite Powder Preparation by New Technology

Dendritic Strontium Tungstate Crystal Preparation

- Details

- Category: Tungsten Information

- Published on Sunday, 06 January 2019 15:08

- Written by meiwei

- Hits: 545

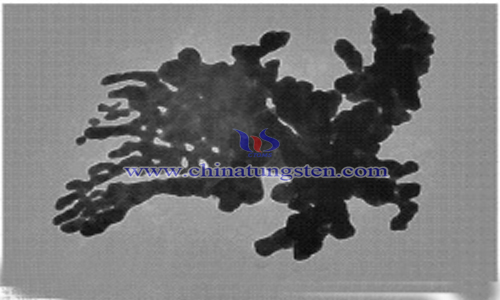

Strontium tungstate is a very important functional material in tungstate. It is widely used in many fields such as photoelectric materials, gas sensitive materials, photocatalytic materials, humidity sensitive materials and so on. It is well known that the properties of nanomaterials depend on the morphology and size of nanocrystals. Therefore, the preparation of strontium tungstate nanocrystals with special morphology is of great significance in theoretical research and practical application.

Read more: Dendritic Strontium Tungstate Crystal Preparation

Thin Plate Tungsten-Titanium Alloy Film Lithography Process

- Details

- Category: Tungsten Information

- Published on Sunday, 06 January 2019 15:32

- Written by meiwei

- Hits: 692

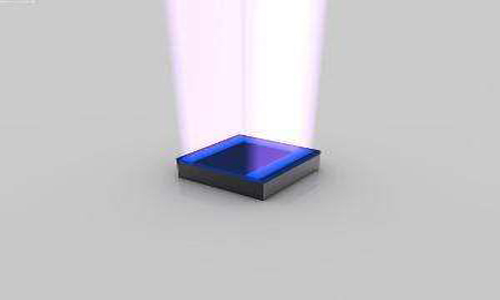

Tungsten-titanium alloy (WTi) is widely used in micromechanical manufacturing. The tungsten-titanium alloy thin films deposited by sputtering process have high density, moderate film stress, excellent surface smoothness, excellent thermal and chemical stability, so they are ideal materials for structural layer and sacrificial layer in the manufacturing of MEMS.

Read more: Thin Plate Tungsten-Titanium Alloy Film Lithography Process

200 Tons Of High-Precision Machine Tools Equipped With Tungsten Carbide Milling Cutters To Help China Aerospace

- Details

- Category: Tungsten Information

- Published on Wednesday, 26 December 2018 09:27

- Written by tang

- Hits: 599

It is reported that the first China International Import Expo opened in Shanghai, China National Convention and Exhibition Center (Shanghai). Among them, the largest exhibit of the “volume” at this fair is a high-precision machine tool with a total weight of about 200 tons – Jinniu Longmen Milling Machine. It comes from one of the world's largest manufacturers of high-precision heavy-duty machine tools, Germany's WALDRICH-COBO Machine Tool Manufacturing Co., Ltd.

The high-precision machine tool manufacturing company was founded in 1920 and has a history of nearly one hundred years. However, in fact, the company was acquired by Beijing No. 1 Machine Tool Plant in 2005. Therefore, strictly speaking, this company should be a subsidiary of Jingcheng Mechanical & Electrical Holding Co., Ltd., a subsidiary of Beijing State-owned Assets Supervision and Administration Commission. In fact, the major domestic technology equipment processing plants, such as aerospace, ship engines, rail transit, etc., can often see the company's products.

According to reports, the precision of this high-precision milling machine is very high, reaching the industry's top level. This "big guy" has a positioning accuracy of 4 μm and repeatability of 6 μm. In addition, it belongs to the important strategic high-tech equipment that China encourages to import and subsidize funds.

However, such a large "volume" high-precision milling machine, "small one" carbide knife (hard alloy milling cutter) is indispensable. why? We can get the relevant information directly from the word "milling machine". Milling machines, as the name implies, are machine tools that use a milling cutter made of a hard alloy milling cutter to machine various surfaces of the workpiece. Specifically, what can the milling machine do? ——It can mill planes, grooves, teeth, threads and spline shafts, as well as more complex profiles.

Why is the tungsten carbide milling cutter usually used? Instead of other materials milling cutters? Because the current use of difficult-to-machine materials is increasing, and the requirements for the mechanical properties of materials are constantly increasing. In addition, the requirements for processing efficiency are gradually increasing. However, traditional blades do not accommodate these new requirements. In short, traditional blades do not meet the high demands placed on the modern machining industry – high precision, high speed cutting and lower cost. However, the carbide-coated blades have high hardness and excellent wear resistance, which can meet the increasing requirements of mechanical processing. That is to say, cemented carbide blades are gradually replacing traditional blades.

Why is this high-precision milling machine or will it help China's aerospace industry? Because of its high-precision machine tools, it has a wide range of applications in high-end equipment manufacturing such as aerospace, rail transportation, automobile manufacturing, mold industry and machine tool production. Among them, in the field of China's aviation industry, with the increase in the number of military aircraft and the advancement of commercial aircraft projects, China will have more than 3,000 new general-purpose aircraft. These aircraft, whether the military is commercial or commercial, the processing of many parts on the fuselage requires high-precision machine tools. Therefore, the carbide CNC blade has more room to play, and the role is quite large. It can be said that if the cemented carbide blade is missing, this German high-precision machine tool is like "a tiger with its teeth and claws pulled out", and you can't do it.

With the strategic goal of China's manufacturing powerhouse - "Made in China 2025" - gradually implemented, China will make breakthrough progress in the ten key areas, and aviation equipment is among them. Aviation equipment includes aircraft, aerospace engines and aerospace equipment and systems. In recent years, domestic market demand has become stronger and stronger, and the aviation industry is facing unprecedented development opportunities and a good environment. At the same time, China's cemented carbide industry restructuring and industrial transformation and upgrading will also be promoted.

However, it must be said that the world's leading CNC blade manufacturers are mainly distributed in Europe, the United States, and Japan. Among them, Sandvik, Kenner, Iskar, Mitsubishi, Kyocera, Sumitomo and other six companies have occupied more than 90% of the domestic market share of cemented carbide CNC blades. This means that while developing high-precision machine tools in China, we must also accelerate the development of hard alloy CNC blades. Because, as we all know, modern CNC high-precision machine tools will generally be equipped with a series of tool products, which means that “the knife will not cut the woodwork” and the “worker must first sharpen its tools”, and also have the “knife” first. And "the device." Without this hard alloy knife, no matter how high-precision the machine tool can only be an axe without a blade, it is white, that is, a wooden stick. All know that wood cut trees, can not be used, the relationship between high-precision machine tools and hard alloy knives is also a rational. Therefore, in the process of promoting the rapid development of China's aerospace industry, CNC blade, as the ultimate product of the tungsten industry chain, also serves as the raw material and processing equipment material for aerospace equipment, not only accelerates the transformation and upgrading of the tungsten industry in China, but also enters the world. The symbolic products of the tungsten industry is also an indispensable indicator of China's manufacturing from a big country to a manufacturing power.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

More Articles...

- Efficient Use Of Superalloy Materials In Rocket Engines And Various Types Of Aerial Vehicles

- Tungsten Carbide Shield Knives Help China's Deepest Subway Subsea Tunnel

- Tungsten Alloy Armor Piercing Projectile, The Secret Weapon Of China’S Rapid Development In Military

- Properties And Uses Of Molybdenum-Containing Stainless Steel

sales@chinatungsten.com

sales@chinatungsten.com