Tungstate Oxidative Desulfurization Catalytic Practice

- Details

- Category: Tungsten Information

- Published on Wednesday, 09 January 2019 22:49

- Written by meiwei

- Hits: 466

With the rapid development of automotive industry, sulfur pollution caused by combustion of automotive fuels is becoming more and more serious. Strict sulfur content standards for gasoline and diesel have been formulated in various countries and regions of the world. Hydrodesulfurization (HDS) is usually used in industry to remove sulfides from gasoline and diesel oil, but for thiophene and its derivatives, due to the steric hindrance effect, the desulfurization effect is poor and the cost is high.

Read more: Tungstate Oxidative Desulfurization Catalytic Practice

Nano Tungsten Carbide Thermal Spraying Technology

- Details

- Category: Tungsten Information

- Published on Wednesday, 09 January 2019 22:39

- Written by meiwei

- Hits: 533

Thermal spraying technology can rapidly prepare a protective coating on the surface of the workpiece, giving the workpiece surface different properties such as wear resistance, corrosion resistance, wear reduction, sealing and so on. WC-based cermets with high hardness and toughness are widely used in aerospace, metallurgy, petrochemical, mechanical and other industries.

Read more: Nano Tungsten Carbide Thermal Spraying Technology

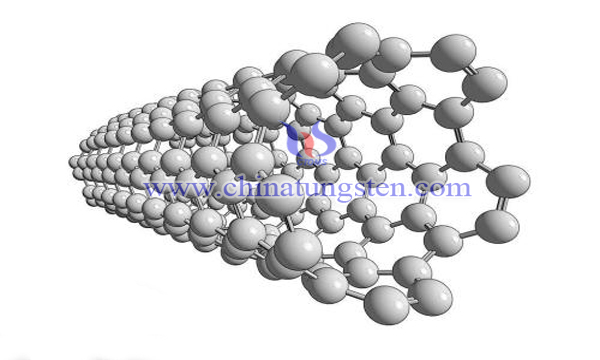

Tungsten Trioxide Nanotubes Preparation by Template Method

- Details

- Category: Tungsten Information

- Published on Wednesday, 09 January 2019 21:54

- Written by meiwei

- Hits: 458

Tungsten trioxide nanomaterials are often used to fabricate high-performance nanodevices because of their unique properties. One-dimensional nanomaterials have become a research hotspot of nanomaterials. At present, the preparation methods of WO3 mainly include V-L-S method, L-L-S method, template method and so on. Template method has the advantages of low cost, suitable for large area ordered array units, and has become the mainstream.

Read more: Tungsten Trioxide Nanotubes Preparation by Template Method

Improvement of Beneficiation Technology for Calcium-containing Tungsten Ore

- Details

- Category: Tungsten Information

- Published on Wednesday, 09 January 2019 22:21

- Written by meiwei

- Hits: 527

Tungsten resources are abundant and varied in China. At present, wolframite is decomposed by alkali and scheelite is decomposed by hydrochloric acid or boiled by soda. For quite a long time, experts at home and abroad generally believed that it was impossible to decompose scheelite by alkali (NaOH) in industry. Until Professor Li Honggui of Central South University put forward the hot-ball milling alkali decomposition process, which broke the convention.

Read more: Improvement of Beneficiation Technology for Calcium-containing Tungsten Ore

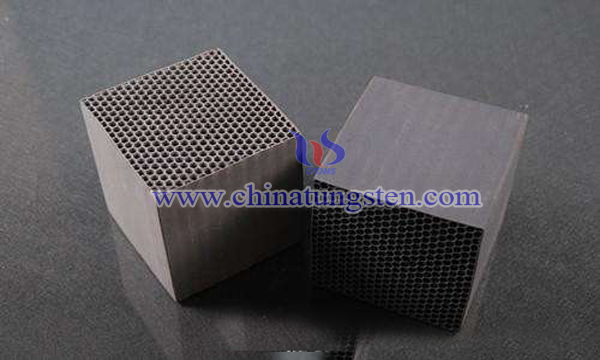

Porous Tungsten Ceramics Electrolysis

- Details

- Category: Tungsten Information

- Published on Wednesday, 09 January 2019 21:48

- Written by meiwei

- Hits: 517

Tungsten is a refractory metal with the highest melting point and lowest vapor pressure in all metals. It has been widely used in aerospace, power electronics and metallurgical industry. Recently, tungsten-based porous ceramics have attracted more and more attention from researchers at home and abroad.

sales@chinatungsten.com

sales@chinatungsten.com