Large Tungsten Enterprise: Positive Negotiated Price

- Details

- Category: Tungsten's News

- Published on Monday, 24 July 2017 12:00

- Written by meilan

- Hits: 727

A large Jiangxi tungsten enterprise yesterday published a long-term negotiated price in the second half of July, which obviously intent to encourage businesses continue to raise quotation.

Read more: Large Tungsten Enterprise: Positive Negotiated Price

Cerium Oxide, Dysprosium Oxide Price - Jul. 21, 2017

- Details

- Category: Tungsten's News

- Published on Monday, 24 July 2017 10:20

- Written by meilan

- Hits: 592

Rare earth prices maintained stability in China. The application of rare earth permanent magnet in the new energy vehicles and other areas performs well currently. Rare earth permanent magnet production enterprises generally increased by 10%-30% in the first half of this year.

Read more: Cerium Oxide, Dysprosium Oxide Price - Jul. 21, 2017

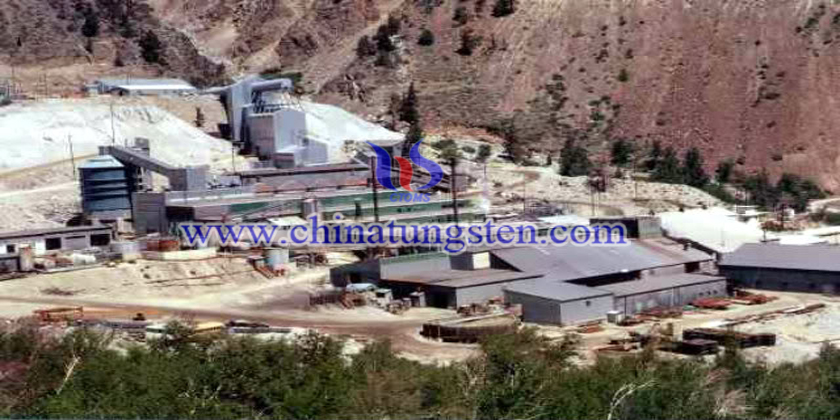

Pine Creek Tungsten Mine History (I)

- Details

- Category: Tungsten's News

- Published on Friday, 21 July 2017 17:14

- Written by Cristina

- Hits: 783

Pine Creek Tungsten Mine locates on the south of Nevada mountain in California, 18 miles northwest from bishop town, altitude is 3300m, is a tungsten mine with centurial history.

Pine Creek Tungsten Mine History (II)

- Details

- Category: Tungsten's News

- Published on Friday, 21 July 2017 17:47

- Written by Cristina

- Hits: 912

During 1936~1953, total output of tungsten in Pine Creek Tungsten Mine is 7613ton. In 1979, Pine Creek Tungsten Mine starts underground exploration, annual output is 2000ton. And keeps being the biggest tungsten producer in America.

Tungsten Price in The Second Half of 2017: Cautiously Optimistic

- Details

- Category: Tungsten's News

- Published on Friday, 21 July 2017 11:02

- Written by meilan

- Hits: 644

The prices of mainstream tungsten products continued to sustaining steady growth yesterday in China, and the volume is small. In the short term, tungsten concentrate’s tight supply is not easy to improve.

The prices of mainstream tungsten products continued to sustaining steady growth yesterday in China, and the volume is small. In the short term, tungsten concentrate’s tight supply is not easy to improve.

Read more: Tungsten Price in The Second Half of 2017: Cautiously Optimistic

sales@chinatungsten.com

sales@chinatungsten.com