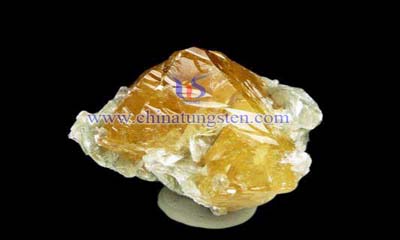

Tungsten Scheelite Beneficiation – Flotation Method

- Details

- Category: Tungsten Information

- Published on Friday, 09 June 2017 11:24

In tungsten metallurgy process, tungsten concentrate usually applies physical method which is gravity separation, tungsten scheelite applies chemical method which is flotation.

What causes such difference? The main reason is the difference in geological characteristic of tungsten ore. Tungsten scheelite exists in skarn ore belt, accompanied by other elements. By separation method can not extract it from other element, so we have to find another way.

Flotation method originated from 1902 and is widely applied in 1913. It is used to beneficiate copper initially, then applied in gold mining industry, then in nonferrous metal mining industry. The principle is by using hydrophobicity of metal element and dealing with a series of chemical process to make different metal elements suspend on the surface of liquid to accumulate, finally to obtain metal. Tungsten scheelite has good flotation property, so it can be beneficiated by this method. Due to fine crystalline of tungsten scheelite, low grade and intergrowth with other mine, in the separation process three flotation agent need to be added: collectors, foaming agent and adjusting agent. According to different choice of flotation agent and process, flotation method can be divided into different types include heating flotation, room temperature flotation, shear flocculation flotation method.

To be more specifically, different flotation method can be divided into 731 room temperature flotation, lime room temperature flotation, etc..

1. Heating flotation method is also called Petrov method. It originated in the Soviet Union, heat and stir tungsten scheelite after coarse selection, separate mineral by different analysis speed on the absorbing and collecting of mineral surface. It is suitable for tungsten scheelite containing calcium. It needs heating and is time consuming, so cost is very high.

2. Room temperature flotation method. It focuses on coarse selection process which highlights coordination application of inhibitor and collecting agent. It is widely applied in skarn tungsten scheelite in China.

3. Shear flocculation flotation method. It is used to deal with fine tungsten scheelite grain, under high speed cutting and stirring to form floc, collect after promoting floatability. I t is applied in low grade tungsten scheelite with intergrowth ore.

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com