Sputter Targets Prepared by Tungsten Powder

- Details

- Category: Tungsten Information

- Published on Monday, 27 June 2016 18:09

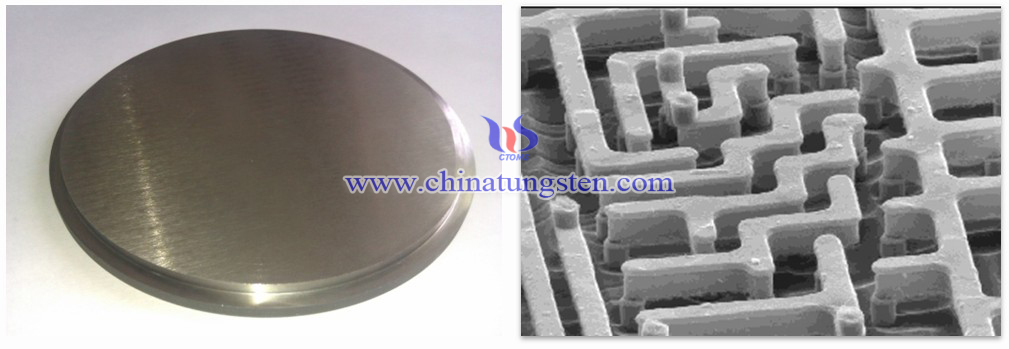

To achieve the high-density tungsten sputter target, a tungsten powder is provided having a powder size smaller than about 50 μm. To obtain a high-purity tungsten sputter target, the tungsten powder is further provided with an oxygen content less than about 500 ppm. In a preferred embodiment of the present invention, the tungsten powder is provided with a powder size smaller than about 20 μm, and more preferably smaller than about 10 μm, and an oxygen content less than about 300 ppm. This tungsten powder is then hot-isostatic-pressed at a temperature in the range of 1200° C. to 1600° C. at a pressure higher than about 15 ksi for a period of at least 3 hours in an inert environment such as argon. The temperature of the hot-isostatic-press (HIP) is preferably about 1400° C. with a pressure of about 40 ksi. At these preferred temperature and pressures, the hot-isostatic-pressing (HIPing) step is preferably performed for about 7 hours.

The HIPing method requires the use of a capsule for containing the powder material during pressing. The capsule material must be capable of substantial deformation because the HIPing method uses high pressure to achieve about a 50-70% volume reduction. Furthermore, the capsule material must have a melting point higher than the HIPing temperature. Thus, any material of sufficiently high melting point that can withstand the degree of deformation caused by the HIPing process is suitable for the present invention. Suitable materials may include, for example, beryllium, cobalt, copper, iron, molybdenum, nickel, titanium or steel.

A cold-isostatic-pressing step prior to the HIPing step is recommended for target diameter/height ratios of greater than about 3. This consolidated powder can then be machined using known techniques, such as electro-discharge machining, water-jet cutting or a regular mechanical lathe. Once machined, the consolidated target blank can be bonded to a backing plate using known methods, such as soldering with a lead-tin or indium/tin solder.

The sputter targets fabricated by this process have a density higher than 97% of theoretical density, and normally, a 99% density can be achieved through the use of the smaller particle size starting powder. Thus, the combination of the HIPing process with a small particle size starting powder produces a highly dense tungsten sputter target. This high-density reduces particle generation from the targets during sputtering.

High-purity sputter targets may also be produced by using a starting powder of high purity. For example, a starting powder having a metallic purity higher than about 99.999% consolidated by HIPing can produce a sputter target having a metallic purity of at least about 99.9995.

The oxygen level of the targets produced by the present invention is at least about 100 parts per million less than the starting powder. This can further be achieved by using a powder capsule made of such materials as titanium, iron or alloys thereof. It is believed that because oxygen in the powder material, such as in the form of WO2, is not stable at the high temperatures used in the HIPing process, the capsule material will react with the oxygen. Thus, it is believed that these powder capsules can act as an oxygen absorber to reduce the oxygen level of the tungsten by more than 100 ppm. The lower oxygen content in the sputter targets of the present invention results in a decrease in the resistivity in conducting films. Thus, any material that reacts with unstable oxygen and meets the melting point and deformation requirements discussed above is a suitable material for use in the present invention. Morever, less alkaline contaminations are picked up during the consolidation process of the present invention by the elimination of graphite molds. The powder capsules of the present invention, such as Ti or Fe capsules, contain very low alkaline content, which will not escape or evaporate from the capsule during HIPing. Reducing alkaline elements in the films reduces leakage of the gate insulation in the integrated circuit, which results in improved reliability of the devices. Furthermore, the hot-isostatic-pressing used in the method of the present invention uses lower temperatures and higher pressure than previous methods, which avoids grain growth of the target material. Fine grains in a sputtering target will improve the uniformity of the deposited film.

| Tungsten Powder Supplier: Chinatungsten Online tungsten-powder.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com