Tungsten Carbide Button — Profile Optimization

- Details

- Category: Tungsten Information

- Published on Friday, 24 June 2016 18:09

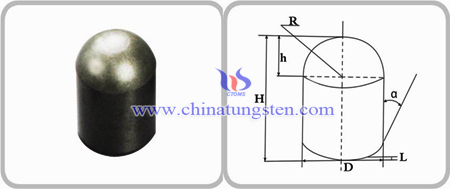

Most of tungsten carbide button profiles are round and bullet-shaped. But in the process of using, conventional round tungsten carbide buttons are prone to be passivated and affects the efficiency of drilling; bullet-shaped tungsten carbide button has tapered crown and small ball radius, so it will be broken easily because of the deficiency in matrix strength in the large impacting power and the hard rock formation. Therefore, tungsten carbide button profile has a significant effect on the performance, which button profile optimization becomes a direction of research.

Based on spherical stamper effective rock breaking mechanism and constant bending stress theory, domestic researchers design blunt-resistant button. It combines the advantages of round buttons and bullet-shaped buttons, the crown consists of spherical shape cap and approximate cone; Wherein the body is subjected to the spherical cap spherical stamper rock breaking, approximate cone dovetail die broken rock, broken rock dominated the first spherical stamper, the stamper wedge after breaking rock, giving the formation of a common rock-breaking effect. In addition, by analyzing the stress distribution of the rock under the spherical die and wedge die proved more rock-breaking effects resistant carbide ball blunt teeth, drilling speed faster, and better impact toughness, not easy to be passivated.

There are experimental data shows that adopt blunt-resistant carbide button, the life and average drilling rate is 36% and 28% higher than bullet-shaped buttons. Another optimized button is composed of fore super-hard sphere and secondary super-hard sphere, the fore super-hard sphere produces shear after breaking rocks; when the drill impacts the rock again, the secondary super-hard sphere impacts on the shear and breaks the rocks repeatedly. This makes carbide button drill bit when drilling footage longer need to drill and drill bit protrusion treatment, but also to maintain a good rock fragmentation capability and self-sharpening performance.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com