Tungsten Bronze Doped Rare Earth Tungsten Electrode Material Preparation

- Details

- Category: Tungsten Information

- Published on Sunday, 12 June 2016 17:45

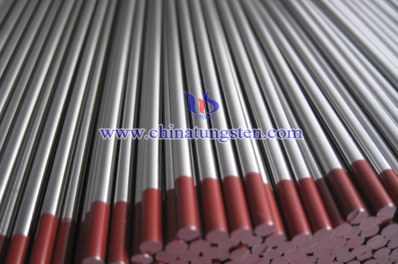

Tungsten has a high melting point, high temperature strength, high thermal electron emission ability and other characteristics, add a low electron work function of the rare earth cerium, lanthanum, yttrium tungsten-based materials to obtain the best application in thermal electron emission materials widely applied to the inert gas welding, plasma welding, cutting, thermal spraying and electric vacuum and other fields. Its emergence and development led to the development of welding technology, large-scale structure of the construction of skyscrapers, large-span bridges, pipeline pressure vessels, ships, etc. are inseparable from the arc welding technology. Electrode material is not only required reliability and stability also requires materials, low cost.

The rare earth oxide dispersion strengthened as the second phase is added to the tungsten matrix, can improve the recrystallization temperature of tungsten electrodes, reducing the electron work function, prolong life and improve the overall performance of the material, particularly more rare earth compound added enable a wider range of current carrying electrodes, welding performance is better than thorium tungsten oxide doped twice generate hydrogen reduction of tungsten powder binder is added molding, with two pre-sintering temperature zone, vertical melting sintered tungsten second phase of ownership, diffusion uneven, timber processing rate and other defects. Thus, high-performance, low-cost needs to be prepared tungsten electrode materials to meet the high-end equipment manufacturing industry is particularly urgent.

A method for preparing a rare earth tungsten electrode material, characterized in that: it comprises the following steps:

1. Pre-reduction, selected ammonium paratungstate as GB / T10116- 2007 in APT - 0 grades , reduction furnace through the four belt zone, the generate hydrogen reduction Fisher particle size of 8 μm-12 μm ammonium tungsten bronze.

2. Doping, ammonium tungsten bronze wet incorporation of cerium, lanthanum, yttrium nitrate solution of rare earth elements or in binary or ternary, after stirring, mixing, drying, rare earth compounds adsorbed in the pores of ammonium tungsten bronze to give 1.0% of total rare earth doped ~4.0% ammonium tungsten bronze.

3. Hydrogen reduction, the process 2 resulting ammonium doped tungsten bronze reduction with six zone temperature zone furnace in a reducing temperature of 630 ° C~960 ° C, the hydrogen flow rate of 2.0 m3 / h~3.0m3 / h, hydrogen dew point <-60 ° C, the cycle push the boat speed 30min~40min , installed capacity of the boat under 320g~420g process conditions to prepare Fisher particle size 1.20 μmι~2.2 μm doped tungsten powder.

4. Forming the C-doped tungsten powder loading 28 ± 0.2mm diameter elastic modulus kit, using a cold isostatic pressing machine, the maximum pressing pressure of 160 Mpa~180Mpa, get tungsten billet of size Φ21~22 x 500.

5. Pre-sintering, molybdenum boat will step 4 resulting tungsten billet is placed under the protection of hydrogen by 1200 ° C~1350 ° C pre-sintered 30min ~45min.

6. Incipient fusion sintering, the resulting step 5 tungsten billet placed in a sintered hood, under the protection of hydrogen dew point <-60 ° C, the sintering temperature, sintering system for the period of warming, some insulation, sintering current within 12min increased from 0 to 2800-3000A insulation 10min, current / time parameters warming 0-3000A / 12min, insulation 3000A / 10min, cooling, discharge, output for the IF induction sintering tungsten.

7. IF induction sintering the resulting step 6 tungsten crucible disaster, the dew point <-60 ° C, a flow rate of 2.5 ± sintered 0.4m3 / h of hydrogen under the protection of the sintering heating system into three sections, three sections of insulation, heated from room temperature to the first section 1600 ° C -1800 ° C, time 4h, insulation 2h; the second section heated from 1600 ° C-1800 ° C to 1900 ° C -2100 ° C, time 3h, insulation 2h; by the third section, temperature was raised to 2200-2400 ° C from 1900-2100 ° C, time 3h, insulation 6h, stop heating, cooling to 200 ° C, the material.

Preparation difference rare earth tungsten electrode material of the present invention is the use of ammonium tetragonal tungsten bronze doped material, doped, further reducing the production of tungsten powder, cold isostatic pressing, sintering and melting temperature vertical IF induction sintering, its mechanism and innovation lies in:

1. The present invention is the choice of more micro-cracks, large specific surface area of ammonium tungsten bronze for doping material, cerium, lanthanum, yttrium rare earth nitrate solution was easy to penetrate deep into the interior, strong adsorption capacity, good doping effect.

2. The advantages of the present invention uses ammonium doped tungsten bronze-step reduction of direct generation of tungsten powder, make full use of six zone-zone furnace and reducing ammonium tungsten bronze easily reducible, and tungsten powder particle size analysis showed a good normal, cold isostatic pressing to create the conditions.

3. Sintering system of the present invention uses a sintered if induction sintering and sintering combination enables high-temperature sintering temperature is lower than 80% of the fusing current conditions, the low melting point volatile impurities thoroughly, rare second phase crystallization fine grain and uniform, rare earth elements to maintain greater than 95%, do not cut the head and increase the yield, small medium frequency induction sintering heat loss, electricity consumption dropped significantly and the like.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com