Tungsten Carbide Picks Failure Mode

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 June 2016 16:16

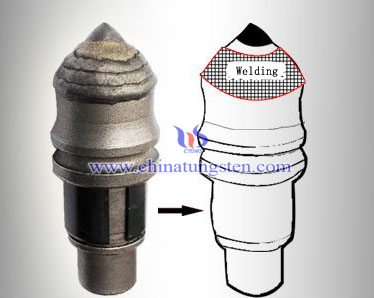

Tungsten carbide picks are composed of carbide button by the brazing alloy and structural steel, generally used for direct shearer cutting, coal mining, so it is also known as coal buttons. Tungsten carbide picks cut coalseam by impact rotation, which requires withstanding high pressure, shear stress and bending stress at the same time. Not only periodic and alternating impact load, in the process of drilling the friction heat seam cutter and intense friction will be also produced, and throughout the wear process also may be accompanied by local yielding, more contact with the mechanical behavior of fatigue, corrosion and breakage.

Take YG11C tungsten carbide mining button as example, from the fracture of buttons after failure, in the coal excavation process, due to impact load surface at high pressure stress, carbide cutter block collapse occurred. Because coal seam geological uncertainties, buttons can not be held in the excavation and seam completely good contact, and mixed with a certain seam gangue, which also makes poor contact or even inevitable increase the area of contact does not occur. Such a state of stress in the alternating load impact effect is prone to fatigue and thermal fatigue cracking. Furthermore, tungsten carbide pick will be damaged by the stress concentration caused by micro defects on the surface or inside tube.

According to the failure modes and the reasons of tungsten carbide picks, we can improve the properties by adjusting the particle size, the composition and the proportion. First of all, Co content should not be too low, because it can improve the thermal fatigue, enhance plasticity, stress relaxation of the alloy and so on. But increasing Co content will have an influence on the wear resistance to some extent, according to the hardness of the coal seam, generally controlled between 8%-13%. Next, the granularity of WC grains and the proportion is also significant, fine grain WC particles total surface area decreases, the specific surface area increases, the mean free path of Co improves, the equivalent profile improves Co content, will help to improve the fracture toughness of the alloy. In order to enhance Co phase, the use of appropriate heat treatment process is a relatively effective way, and use the existence of polymorphic transition phase to produce other enhanced face-centered cubic cobalt, so as to achieve the purpose of toughening carbide picks.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com